|

(pressing HOME will start a new search)

|

|

Teaching

Mechanical Construction Estimating: Information for Course Development

John R. KoontzDepartment

of Building Construction Purdue

University West

Lafayette, Indiana |

James T. RichardDepartment

of Construction Management Florida

International University Miami,

Florida |

|

An increasing number of mechanical contractors are utilizing computerized estimating systems. In parallel, there has been a strengthening request from the mechanical construction industry to provide mechanical construction education at the university level. With the development of a mechanical construction management curriculum comes the question of whether to include computerized estimating, and if so, to what degree. This paper analyzes the data collected from a survey of mechanical contractors and provides information regarding computerized construction estimating for use in the development of a course in mechanical construction estimating. The developmental information received is directed primarily at computerized estimating specific to mechanical construction. This paper identifies the computerized estimation systems being used, the profile of the contractors using them, the degree of usage in the industry, and the mechanical contractors AE opinions regarding the importance of computerized estimating as a necessary skill for newly-hired college graduates. The information presented in this paper is offered to assist educators in determining the content of a potential mechanical option program. Keywords:

Contractor,

Mechanical Construction, Course Development, Computerized Estimating,

Digitizer, Estimating, Survey, Estimation, QuickPen, Teaching. |

Introduction

For

the past two years, the Department of Building Construction and Contracting at

Purdue University has been in the early stages of creating a Mechanical

Construction Management Option program. The Building Construction department,

always an advocate of collecting industry advice and support towards the

establishment of new educational programs, established an ad hoc mechanical

advisory council. Since its inception, several advisory meetings between the

mechanical contractors and the Building Construction Department have been held

to determine industry needs, departmental needs and educational goals, and the

future direction of the program.

Through

these meetings, the advisory council determined that the mechanical option

program should contain a course in mechanical construction estimating. In

addition, the mechanical construction estimating course should include the use

of a computerized estimating system specific to the mechanical construction

industry. Advisory council mechanical contractors were adamant in their belief

that a student should be taught estimating specific to mechanical

construction. They felt strongly that the completion of courses in general

construction estimating alone were not sufficient for the graduate who accepts

employment with a mechanical contractor. As a result, all parties agreed that

mechanical contractor information regarding computer estimating usage should

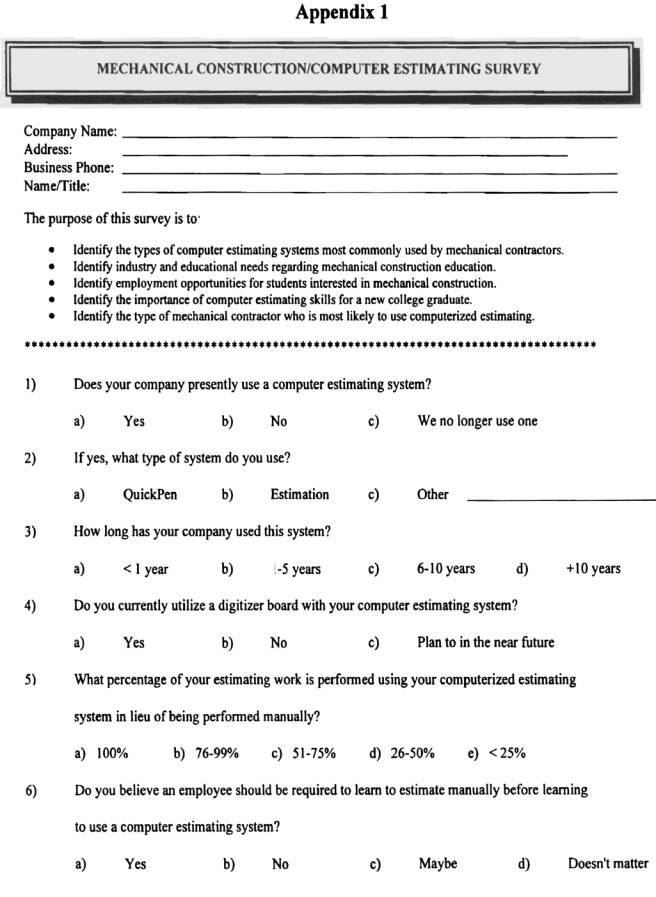

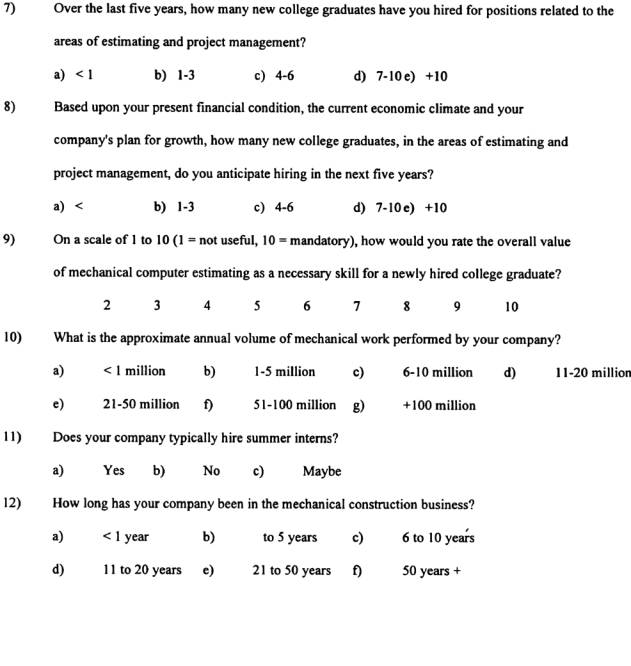

be collected. Therefore, from November 1993 to February 1994, a survey was

conducted by Purdue's Building Construction department to provide useful

information in developing the course. Fifty Indiana mechanical contractors of

various annual volumes were surveyed to collect information relative to

estimating and to potential graduate placement. For reference, the survey

instrument can be found in Appendix 1. The primary intent of the survey,

relative to mechanical construction estimating, was to identify the following:

-Industry

and educational needs

-Importance

of computer estimating skills for new college graduates

-The

profile of the mechanical contractor using computerized estimating

As

a note, this survey instrument additionally contained several questions

regarding summer internships and graduate placement. This paper does not

address these issues as they are not directly related to the development of an

estimating course in mechanical construction.

The

Study

Presented

here are the results of the study.

What

is the profile of the mechanical contractors who were surveyed?

The

profile of the fifty mechanical contractors surveyed covers the entire

spectrum from very small to very large. The contractors were found to have

annual volumes which ranged from one million to over 100 million dollars. The

majority of the mechanical contractors surveyed are members of the Mechanical

Contractors Association of Indiana (MCAI).

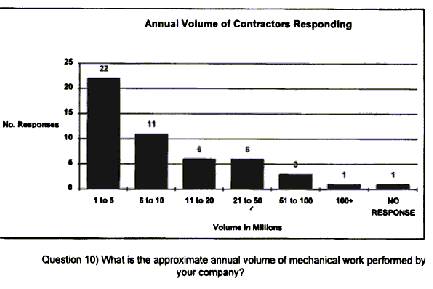

The

survey instrument requested information regarding the annual volume of the

contractor to determine if estimating methods and needs varied between smaller

and larger contractors. Their responses are displayed by contractor annual

volume and number of contractors in Figure 1. Ninety percent of the responding

contractors had volumes of 50 million or less. One contractor, due to privacy

concerns, demurred to provide information regarding annual volume.

|

|

|

Figure

1. |

The

number of larger contractors as related to the number of smaller contractors,

as presented in Figure 1, was discussed with Mr. Roger D. Beesley, the

Executive Vice President of the Mechanical Contractors Association of Indiana.

Mr. Beesley's comment was "these percentages by size appear to be a

typical cross section of the mechanical contractors in the Midwest. There are

many small contractors and a few large contractors, just as one would

expect."

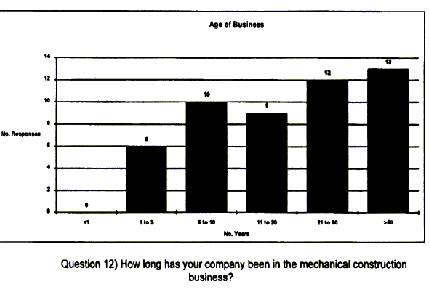

Information

regarding the number of years that the responding contractors have been in

business was collected to determine if contractor age affects or is related to

computer estimating usage. Figure 2 exhibits a range in ages. The range in

ages of responding contractors is approximately 1 year to over 50 years old.

Eighty eight percent of the 50 businesses who responded are 6 years old or

older. Figure 2 indicates a fairly equal distribution of businesses in each

age category.

|

|

|

Figure

2. |

Do

mechanical contractors use computerized estimating?

Computers

today are an accepted tool for mechanical construction companies. In the early

1970's, most contractors initially used mainframe computers for the purposes

of data processing and bookkeeping. During the mid-to-late 1970's, the

construction market and the national economy experienced drastic change.

Operating costs soared and the number of competitors grew. To adapt to these

changes, contractors were forced to become more cognizant of labor and

material costs, and to find methods to track and control them. In the 19801Es,

contractors began to use personal computers for frontline functions such as

project management and estimating to gain more control of their project costs.

This new application of the computer helped contractors to streamline their

businesses and maintain their market share.

To

continue to meet new challenges head-on, many contractors are improving their

efficiency at the onset of a project by utilizing computer estimating systems.

Computer estimating systems not only improve estimating efficiency, they

improve material ordering, field labor scheduling, and trade coordination.

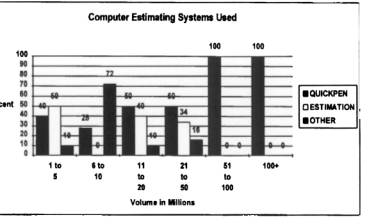

To

incorporate contractors' current utilization of computerized estimating,

information was collected and evaluated from local Indiana mechanical

contractors. Sixty six percent of the responding contractors use some form of

computerized estimating system. Figure 3 represents the responses received

from contractors by various annual volumes regarding their usage of

computerized estimation.

As

indicated in Figure 3, contractors surveyed with a volume of greater than 5

million maintain a much higher percentage of computer estimating usage than

those with a volume of less than 5 million. Only 45 percent of those

contractors surveyed who have an

annual sales volume of less than 5 million maintain usage of some form

of computerized estimating. From this data, it appears that the higher a

contractor's volume, the more likely the contractor is to use computerized

estimating. 100 percent of the contractors surveyed with an annual volume in

excess of 20 million use some form of computerized estimating.

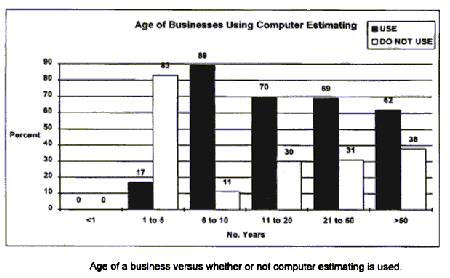

The

contractor age ranges collected and illustrated in Figure 2 were drawn upon to

assist in answering questions such as, "Do younger companies or older

companies tend to use computer estimating?" Figure 4 displays which age

ranges use computer estimating. In Figure 4, the contractors surveyed who most

use (89 percent usage) computer estimating are in the 6 to 10 year old range,

while the contractors in the less than 6 years old range appear to be the

least likely (17 percent usage) to use computer estimating. Stated

differently, 83% of the companies less than 6 years old do not use computer

estimating. A possible assumption regarding the younger companies is that they

are yet to establish themselves financially and may be unable to make the

major capital investment required to acquire a computer estimating system.

|

|

|

Figure

4. |

A

further observation from Figure 4 includes noting that the percentage of

non-users (other than those companies less than 6 years old) increases as the

age of the companies increases. Although computerized estimating systems have

been in use in some form since the late 1960's, not all contractors have

chosen to use them; and many of those who have chosen to use them only started

recently. It would be interesting to learn the reasons for non-usage, however,

the answer is beyond the scope of this survey.

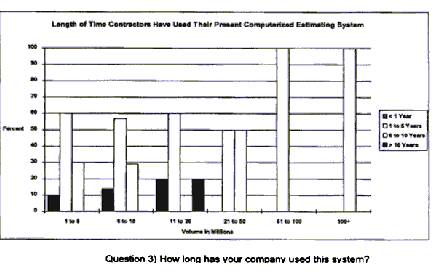

How

long have mechanical contractors been using computer estimating?

In

reviewing the information provided by Figure 5, one can see that although

various forms of computerized estimating systems have existed lb for more than

25 years, the majority (the author &E additional analysis of the data

found 70%) of the users have used their present computerized estimating

systems for less than 6 years. This figure includes those companies who have

replaced their archaic systems with newer, more advanced systems, and those

companies who have acquired their first systems. Based on this statistic, such

newness would seem to warrant educational support by academia to provide

graduates who are able to conduct computerized mechanical estimation.

|

|

|

Figure

5. |

Which

computer estimating systems do mechanical contractors use?

The

number of computer estimating systems available today seems infinite. The

trade journals of the mechanical construction industry are peppered with

advertisements from vendors offering a new, exciting, and cost-effective way

to estimate mechanical construction work. To a new contractor or a contractor

unfamiliar with computerized estimating, this sea of choices must appear

confusing. In addition to the heavily advertised packaged vendor systems, many

contractors over the years have created their own personalized systems. When

surveyed, the responding contractors were asked to name the brand of computer

estimating systems their companies currently use. The results are illustrated

by contractor annual volume in Figure 6.

|

|

|

Figure

6. |

Two

major brands, QuickPen and Estimation, are used by nearly 73 percent of the

contractors surveyed. This fact came as no surprise to the authors as QuickPen

and Estimation are seasoned professional corporations who provide quality

systems and retain major advertising budgets, and who have extended aggressive

sales efforts to members of mechanical trade organizations in the past decade.

Responses from the remaining 27 percent, in the Other category, contained many

personalized systems of non-familiar brands, and an occasional mention of

known brands such as MCI and WinEst. A noticeable pattern is that apparently

the larger the contractor is, the more likely the contractor is to use the

QuickPen system, and the smaller a contractor is, the more likely the

contractor is to use the Estimation system. According to Mr. Stephen Churchill

of Estimation, Inc., "This is likely because in the early-to-mid 1980's,

QuickPen made

a

major sales concentration towards capturing the market of the top 100

contractors in the country. The Estimation marketing effort in past years has

been directed toward the more numerous smaller companies. Our system requires

a much smaller capital investment than QuickPen and therefore has greater

appeal to smaller companies with smaller budgets." Mr. Churchill reports

that "due to major software developments, such as the Estimation system's

compatibility with Microsoft Windows, Estimation has recently made great

strides in capturing a larger share of the big contractor market."

Do

mechanical contractors use digitizers with their computer estimating systems?

Most

of the computer estimating systems used in the late 1970's and early 1980's

required the manual input of all takeoff quantities. After manual data input,

the old systems would collect the appropriate material and labor units from

the data base, calculate automatic by-products, and then extend labor and

material items to produce subtotals and totals. The data input function of the

old systems was slow and tedious for even the quickest estimators. Performing

any type of material substitution analysis or labor unit comparisons prior to

bid time was difficult, time consuming, and often required all data to be

re-entered for each analysis.

To

overcome the tedious takeoff and entering of quantities, rapid electronic

takeoff means were developed. Most of the newer, more advanced computerized

estimating systems of the late 1980's and early 1990's, such as Estimation and

QuickPen, provide for the electronic takeoff of materials by using a digitizer

board and pen. In addition, most of the newer systems allow the estimator to

choose between manual or electronic quantity input. Even the most open-minded,

experienced estimator might not initially trust the digitizer pen for input,

so providing the option to work both ways allows flexibility.

Most

estimators who have experienced both the manual and digitizer methods of

quantity takeoff typically find that the digitizer method is a great saver of

time and aggravation. Mr. Robert Snodderley, Chief Estimator for. the Ed Grace

Company, a 10 million dollar per year, Lafayette, Indiana, mechanical

contractor, states, "I'm 50 years old and have been estimating for 27

years. As with the Xerox and the FAX machines, I can't imagine manually taking

off a large project since we acquired our QuickPen system and digitizer.

Mechanical estimation involves the quantification of many intricate parts and

is time consuming. The digitizer saves me 20%30% of the normal estimating time

involved."

Like

any saver of time, there is the drawback of initial cost. The option of adding

a digitizer to a computer estimating system can cost as much as $1500 to $3000

for hardware alone.

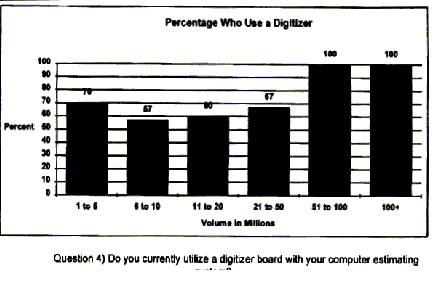

Of

me contractors surveyed who use a computerized estimating system, 70 percent

use a digitizer for quantity takeoff, and 3 percent plan to use a digitizer in

the near future. Figure 7 exhibits by contractor annual volume the percentage

of mechanical contractors who use digitizers with their present computer

estimating system.

|

|

|

Figure

7. |

It

is apparent that most of the contractors surveyed find it beneficial to use a

digitizer with their system. However, it is unknown how many who do not have

digitizers with their systems would use one if it were available.

To

what extent do contractors use their computer estimating systems?

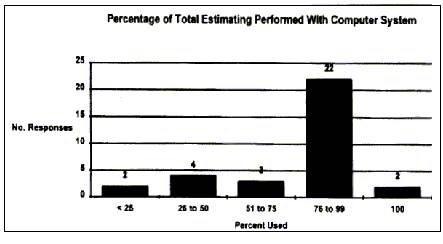

Although

the computer is used for a substantial amount of estimating work by the

contractors surveyed, 25 percent of the estimating work is still completed

manually. The data shows that nearly 73 percent of the contractors who use a

computer estimating system use it to complete 75 percent or more of their

total estimating work. Figure 8 displays a percentage breakdown of the total

responses to Question 5 regarding estimating work utilizing the computer.

|

|

|

Figure

8. |

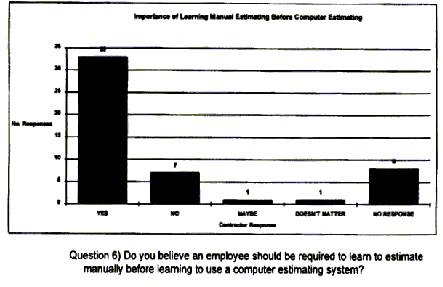

Should

manual estimating be taught before computer estimating?

With

the majority of the surveyed contractors using computer estimating systems for

the majority of their estimating work, it would appear that emphasis on

computer skills for an estimating employee should be the strongest. However,

the data collected and illustrated in Figure 9 indicates that the importance

of learning manual estimation skills is also felt strongly by those same

contractors.

|

|

|

Figure

9. |

Thirty

three of forty two contractors (79%) who responded to the importance of manual

skills education felt strongly that an employee should be required to learn

manual estimation before learning to estimate with the computer. Only 17

percent felt strongly that it was not necessary for an employee to learn

manual estimating skills first. Five percent did not feel strongly committed

either way, and 8 of 50 contractors did not respond.

Is

it important to teach computer estimating specific to mechanical construction?

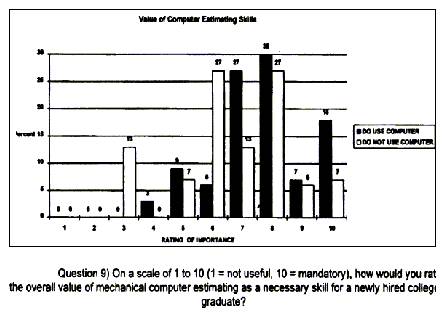

How

would you rate the overall value of computer estimating specific to mechanical

construction as a necessary skill for a newly hired college graduate? This

question was asked of the 50 mechanical contractors to determine the

importance of a computer estimating course specific to mechanical construction

in a mechanical construction option curriculum. The contractors were asked to

rate the importance on a scale of 1 to 10, with 1 being not useful, and 10

being mandatory. Figure 10 illustrates the responses to this question of

overall value from both users and non-users of computer estimating.

|

|

|

Figure

10. |

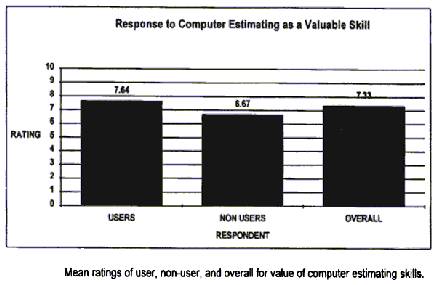

Figure

11 displays the mean of the information from Figure 10.

|

|

|

Figure

11. |

The

responses to the question regarding the overall value of computer estimating

specific to mechanical construction as a necessary skill fog newly hired

college graduates, from both uses and non-user contractors, were surprising. I

the authors had been asked to speculate before receiving the survey results, a

strong Mandatory (computer estimating skills specific to mechanical

construction is important) response from the users of computerized estimating,

an a strong Not Useful (computer estimating skill; specific to mechanical

construction is not important) response from the non-users of computerized

estimating would have been expected. However, a weaker Mandatory response from

users, and a stronger Mandatory response from non-users was received.

Strong

Mandatory responses to the value of computer estimating skills from non-user

contractors, as well as from user contractors, would tend to indicate that the

majority of the contractors surveyed have a high opinion of the importance and

necessity of computer estimating skills for a newly-hired college graduate.

One speculation regarding the strong Mandatory responses from the non-users is

that perhaps the non-users (34% of those surveyed) will someday wish to use

computer estimating, and will seek graduates educated in computer estimating

specific to mechanical construction. Regardless of the non-user reasons for

valuing computer estimating, both the users' and non-users' responses reflect

positively towards the importance and necessity for computerized estimating

specific to mechanical construction within a mechanical construction

curriculum.

Conclusion

From

this study, several valuable pieces of information have been acquired which

will assist in the development of estimating courses in mechanical option

programs. The following significant statements may be generally concluded from

this study:

-

Both non-users and users feel strongly about the importance of graduates who

are knowledgeable about manual estimation as well as computer estimation

-

66% of Indiana mechanical contractors surveyed use some form of

computer estimating

-

73 % of the users surveyed use QuickPen or Estimation 70% of the users

surveyed use a digitizer with their computer estimating system

-

70% of the users surveyed have used their system for less than 6 years

-

83% of the contractors surveyed who are less than 6 years old are not

users

-

55% of the contractors surveyed with an annual volume of less than 6

million are not users

Although

additional study and development are required, the initial direction and

content of estimating courses in mechanical option programs can be determined

by the above conclusions.

The

following statements should be used as guidelines for initial course

development:

Students

should be taught manual estimating prior to computer estimating.

Most

contractors surveyed felt strongly that a graduate learn the fundamentals of

estimating for mechanical construction by first learning manual estimating.

Among the reasons for their belief lies the fact that projects must still be

estimated even if the computer stops working.

Students

should be taught computerized estimating for mechanical construction.

Most

Indiana mechanical contractors surveyed use some form of computerized

estimating, and they felt strongly that a graduate possess computerized

estimating skills for the mechanical construction industry. Therefore,

graduates pursuing work with mechanical contractors should be literate in the

area of computerized estimating specific to mechanical construction.

The

computerized estimating portion of the mechanical option course should be

taught using an industry standard system such as QuickPen or Estimation with a

digitizer board and pen.

Most

contractors surveyed presently use a QuickPen or Estimation system. Therefore,

if financially feasible to the university, the computerized estimating systems

and hardware used in mechanical construction courses should replicate what

industry is using. Graduates possessing computerized estimating skills

specific to mechanical construction will be in increasingly greater demand. It

is evident that

most

of the contractor users surveyed were new users with much to learn about their

systems. It is probable that several smaller and younger mechanical

construction companies who will survive and grow older are likely to acquire

computer estimating systems. Educators must respond to this growth by ensuring

that manual and computerized estimating skills specific to mechanical

construction, with industry's widely-used systems, be provided in the

curriculum.

References

Adcox,

J. W., Jr., (1993). Construction advisory committee by the year

2000.Proceedings of the 29th Annual Conference of the Associated Schools of

Construction. pp. 7-11.

Chick,

D. (1992, July 7). Changing role of the estimator. Cost Engineering. pp.

23-25.

Seltz,

A. (1989, July 6). Mouse driven program redefines estimating. ENR. p. 37.

Matthewson,

C. (1990). The influence of computers on estimating and bidding. Proceedings

of the 26th Annual Conference of the Associated Schools of Construction. pp.

101-106.

Mezick,

D. (1993, October). Pen computing catches on. Byte. pp. 105-106.

Wallace,

G. M., Killingsworth, R., Cooper, T. E., & Love, T. A. (1990). The use of

CADD interactive software in an advanced estimating course. Proceedings of the

26th Annual Conference of the Associated Schools of Construction. pp. 35-40.

Ward,

J. R., & Schultz, D. (1993, January). Digitizer renaissance. Byte. p. 251.

Interview with Stephen K. Churchill, Field Training Representative for

Estimation, Inc., September 23, 1994.

Interview

with Roger D. Beesley, Executive Vice President for the Mechanical Contractors

Association ofIndiana, Inc., September 27, 1994.

Interview

with Robert J. Snodderley, Chief Estimator for Ed Grace Company Mechanical

Contractors and Engineers, October 6, 1994.

|

|

|

|