(pressing HOME will start a new search)

- ASC Proceedings of the 27th Annual Conference

- Brigham Young University-Provo, Utah

- April 18-20, 1991 pp 103-106

|

(pressing HOME will start a new search)

|

|

RESEARCH

AND DEVELOPMENT OF FLEXIBLE PAVEMENT INFRASTRUCTURE

|

Shahram

Varzavand, Ganesh Shrestha, Stephan Egger and

M.F. Fahmy University of Northern Iowa Cedar

Falls, Iowa |

| Due

to current environmental awareness and concerns across the nation, there

exists a great opportunity for professionals in construction to get

involved in presenting a concrete solution to these environmental

issues, as well as modifying or improving the current construction

materials. Professionals involved in construction education and industry

are well aware of desirable and undesirable properties of construction

material.

Benefits

of asphalt rubber pavements are not limited to reduction of landfill

material and space. Laboratory and field tests across the nation and by

European countries have yielded a wealth of knowledge regarding improved

properties of asphalt, such as: skid resistance, reduction in traffic

noise, improved ductility at low and high temperatures. The

focus of this paper is not only to improve an existing construction

material, but also provide an alternative solution to the growing

environmental hazard of waste tires. |

TECHNOLOGY

The

Department of Energy has reported an estimated 2-3 billion tires exist in

stockpiles, landfills, etc., in the United States. The stockpile grows by 279

million annually.

The

wasted tire is not biodegradable. Past uses of tires have not created enough

economic demand for their reuse.

The

heating value of tires is 20% higher than that of coal. Burning of the tire for

energy has been used in western Europe and is beginning to develop in the U.S.

The enthalpy of combustion (energy) from burning tires has been used to produce

Portland cement. Several problems with air quality have developed because of

tire burning.

The

1972 oil embargo created a pyrolysis to extract the oil from tires for energy.

This proved to be uneconomical. The availability of crude oil has dropped since

1972.

Asphalt

rubber was pioneered in the United States by Charles McDonald for the City of

Phoenix, Arizona.

Reclaimed

rubber has been added to the asphalt in a paving mix to improve the physical

properties and durability of the asphaltic (flexible) pavements. The Arizona

Department of Transportation and the city of Phoenix have successfully used this

product extensively over the past 25 years.

The

asphalt-rubber process involves heating 80% conventional asphalt with 20%

reclaimed ground rubber (old tires) for about 45 minutes at 375° F.

This heating process causes the rubber particles to swell and produce a softer

and flexible sticky binder. during the process a small amount of oil extender is

added to the mix to reduce the binder's viscosity. This binder can be used for

several asphalt-rubber applications to include SAM, SAMI, Seal coat, Plus-Ride,

Open Graded and Dense Graded systems. A description of these systems include:

Stress

Absorbing Membrane (SAM) also

known as chip seal coat consists of a thin layer of asphalt rubber (less than

0.2 of an inch in thickness) is sprayed over existing pavement and small rock

chips are then added.

Stress

Absorbing Membrane Interlayer (SAMI)

is

used to help prevent reflective cracking. This phenomenon inhibits further

cracking and prevents any footprint of old cracks into the new surface. The

major objective of this system is to place a crack arresting layer between the

old and new surface. This is done by spraying a thin layer of asphalt rubber

over the old pavement surface prior to surfacing with the conventional asphalt.

This process can be repeated as necessary to reach the desired elevation.

Seal

Coat

is another method which is used to seal existing cracking (commonly

called alligator cracking). This type of cracking is very common in cold

climates due to reduction in flexibility (ductility) of the traditional pavement

materials. As a general rule asphalt concrete pavement should be designed with a

binder which behaves flexibly in the cold climate and is semi-rigid in hot

climates.

Plus-Ride

a portion of aggregates (crushed rock) is replaced with rubber granules

from recycled tires.

Open

Graded and Dense Graded

hot mixed asphalt rubber pavements are composed of conventional open and

dense graded aggregates with asphalt rubber binder rather than plain asphalt.

Evaluation of dense graded asphalt rubber by the Iowa Department of

Transportation (MI.R-89-15) indicates that asphalt rubber hot mix outperforms

the conventional asphalt. This year 95% of all asphalt in Mid-America will be

hot mix asphalt pavement (which can be produced by all hot mix plants with

conventional equipment). For example, within a 50-mile radius of Kansas City

over 50,000 tons of rubber asphalt hot mix will be bid for Interstate 29, US 71,

US 24, Kansas City International Airport, and others.

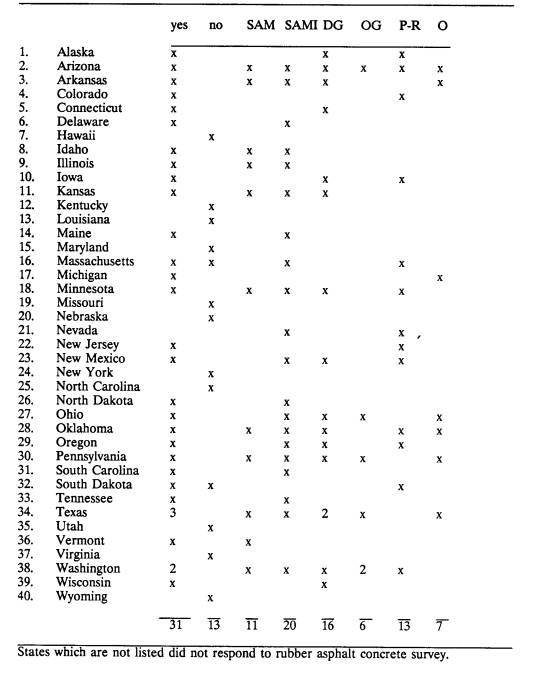

A

national survey conducted by researchers at UNI documented that these systems

have been used and field tested across the U.S. The frequency and popularity of

asphalt-rubber concrete in various state across the U.S. is exhibited in Table

1.

| Table

1. Usage of rubber-asphalt concrete in recent years |

|

In

regard to the over 300 articles collected there exists the need to further

research and field test rubber asphalt concrete systems. Documented benefits of

rubber asphalt concrete include:

|

It

is important to mention that the majority of state Departments of Transportation

across the U.S. support research into the inclusion of rubber into asphalt

pavement.

Asphalt

rubber has been in use for over 25 years and in some cases received overwhelming

positive support while others have received mixed reviews. For asphalt rubber to

be a viable construction material, there needs to be clarity in regard to actual

costs, equipment, as well as the thickness needed. Also there is the need to

have a comparison of costs between this material and conventional asphalt

mixtures.

In

order to evaluate the potential usage of Asphalt rubber concrete on Iowa roads

researchers at UNI have become involved with state legislators, the Iowa

Department of Natural Resources and the Iowa Department of Transportation. In

recent years two major grants in polymer and elastomer studies amounting to

almost $230,000 worth of research monies. These grants represent involvement and

interaction with Iowa legislators, the Iowa Department of Natural Resources and

the Iowa Department of Transportation. The most recent grant ($98,000) with

the

IDOT will be presented in this paper.

The

following includes portions of the research proposal which was submitted to the

IDOT Highway Research Board. The result was a joint venture and partnership

between the construction faculty and representatives of IDOT.

Iowa

has 3,840 lane miles of interstate, 20,300 miles of primary roads and 89,500

lane miles of secondary and county roads. Ninety percent of interstate road

costs and 75% of primary and secondary road costs are financed by federal aid.

County roads are financed by county funds. Additionally, Iowa has extensive

miles of urban streets that are supported by cities and counties. It has been

estimated that Iowa wastes 3.5 million tires each year. Presently, waste tires

are disposed of in designated landfill sites under city/county control. A large

percentage of the waste tires are illegally dumped.

The

whole tires which are stockpiled represent not only a waste of resources but

also a health hazard because of mosquitoes, fires and general contamination of

the environment. The mosquito is an encephalitis borne disease carrier that has

migrated to the Midwest. Tire fires are an environmental risk in the form of

liquid and gaseous emission. The best way of eliminating the environmental and

health hazards associated with tire piles is to minimize and ultimately

eliminate the stockpiling of tires.

Adequate

technology exists to significantly reduce tire stockpiles. Waste tires are

under-utilized because of adverse economics. It is cheaper to throw a tire away

than to recycle it. Until economic forces are reversed, and environmental

concerns addressed, tire stockpiling will be the option of choice. Producers and

importers of tires must become involved and need to assure that such tires are

ultimately managed in a responsible fashion.

ASPHALT-RUBBER

EVALUATION FOR THE STATE OF IOWA:

In

order to evaluate Asphalt-Rubber on Iowa roads, a demonstration project has been

established. The proposed research will be incorporated into Muscatine County

construction project F-61-4(49)--20-70 on US 61 from Muscatine to Blue Grass.

The existing pavement is a 10 inch by 24 foot jointed portland cement concrete

pavement constructed in 1957. The Muscatine project is a 14 mile, 4 inch asphalt

concrete overlay that will probably consist of 2 inches of binder and 2 inches

of surface. The 1988 traffic value was 6490 vehicles per day with 17% trucks.

The project was scheduled for the October 2, 1990, letting. The construction

will be during the summer of 1991.

The

research would consist of three one-half mile experimental sections and two 500

foot Plus-Ride

sections.

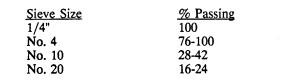

Plus-Ride experimental sections would use approximately 5% recycled rubber

granules of a suggested gradation as follows:

|

These

two sections will depend on the availability of satisfactory rubber granules.

The two 500 foot sections would be placed directly across the road from each

other to avoid Friction Number variations from lane to lane. The rubber granules

will be used in the surface, but not in the binder.

The

three one-half mile, 12 foot wide sections with asphalt-rubber binder will be

separated by one-half mile sections of the conventional mix designed for the

project. The other two comparative conventional mix sections will be adjacent on

either end of the experimental sections. Mix designs for the conventional mix

and the asphalt-rubber binder mixes will be developed at the Iowa Department of

Transportation Materials Laboratory at Ames. Joints will be sawed over the

joints in the existing pavement in 1/4 mile of all asphalt-rubber binder

sections and all conventional binder sections. The asphalt-rubber binder will be

used in both the binder and surface on one section and only in the surface of

the other two sections.

The

University of Northern Iowa (UNI) participation in the research will be

predominately in determining the aging and changing of the conventional asphalt

cement binder and the asphalt-rubber binder over the five year period. Some of

this testing will be in the laboratory and some will be on binder extracted from

cores taken from the construction project. The procedures for these tests are

described in the evaluation section.

EVALUATION

The

Iowa Department of Transportation and researchers at the University of Northern

Iowa will evaluate the research for a minimum of five years after construction.

The Iowa Department of Transportation will drill all cores needed for UNI

evaluations. The UNI evaluation will include the following:

DUCTILITY

TEST

ASTM

D113 Ductility Test Method will be utilized. These test specimens will be tested

at below freezing (intend 20°F), 32°F, 40°F, 70° F, and 100°F.

AGING TEST

ASTM

113 Ductility Test will be used to determine the effects of aging on

(asphalt-rubber) and conventional asphalt binders. Ample specimens will be

produced and exposed to some environmental elements as the test section. It is

assumed that when asphalt is exposed to sunlight, it will lose its ductile

properties and become more brittle. A comparison between ductility of control

group (plain asphalt) and test group (asphalt-rubber) will be made. Specimens

will be tested at 32°F, 40°F, 70°F and 100°F. Scanning electron

microscopy will also be used to evaluate each specimen after failure.

TENSILE CREEP TEST

The

stress-strain properties of cast binder (asphalt-rubber) will be measured in a

tensile creep test under various constant loads at 32°F, 70°F, and

100°F. The test specimens will be cast in a mold which consists of the end

pieces of the ASTM D113 ductility test mold, with 150 mm long straight side

pieces instead of the wedge shape side pieces instead of the wedge shape side

pieces of ductility mold.

The

tensile creep tests will be run in a modified ductility bath, with the free ends

of the specimen supported on a 'raft' made of wood and polystyrene foam.

Specimens will be supported in the same plane as the fixed end. Dead weight

loads will be applied through a thread fastened to the raft and passing over a

pulley. Prior to testing, specimens will be kept in the constant temperature

bath for 60 minutes.

FATIGUE TEST

A

beam fatigue test will be utilized to evaluate the fatigue characteristics of

the asphalt concrete mixes. The fatigue test will be performed by placing the

beams on a flexible sub-grade and applying a repeated load at the center.

Results will be used to determine the relative fatigue life of the mix, and to

estimate the fatigue life of a test section.

Iowa

Department of Transportation testing will include all standard density

determinations on all sections at time of construction. In addition to the

standard project testing of the mix, creep (creep resistance factor under 200

psi compression) and resilient modules will be determined for all three mixes.

Friction testing by ASTM #274 will be conducted annually for five years on all

nine sections. The Iowa DOT Road Rater will determine "deflections"

(compressibility) annually for five years.

Annual

crack and rut depth surveys will be conducted on all sections. The time until

reflection cracks occur will be determined for each test section. The percentage

of reflected cracks will also be determined. Rut depths under a four-foot

straight edge will be determined for both wheel paths.

SUMMARY

Researchers

at the University are examining, reexamining, and in some cases duplicating

previously done research. Additionally, new research areas and perspectives are

also being explored in regard to the

potential

use of rubber asphalt concrete. Special attention is being directed at the

specific tests of Penetration, Marshall Stability and Flow and Ductility. A

major thrust of the rubber asphalt is to identify a mix that would offset the

negative conditions (freezethaw cycle, heat of summer months, etc.)

experienced by road pavements throughout the state of Iowa. There is a growing

awareness for the need to examine the use of recycled materials such as rubber

tire and their incorporation into viable construction materials. This

necessitates that university faculty redirect some

of

their efforts to applied research projects dealing with the solution of these

environmental problems. Currently, there exists unique opportunities and

research monies to work in joint ventures and/or partnerships with state

agencies, such as the Department of Natural Resources and the Department of

Transportation.