(pressing HOME will start a new search)

- ASC Proceedings of the 25th Annual Conference

- University of Nebraska-Lincoln- Lincoln, Nebraska

- April 1989 pp 68-73

|

(pressing HOME will start a new search)

|

|

CONCRETE

COMPOSITES A NEW CONSTRUCTION MATERIAL

|

Norbert L. Lovata Madison,

Wisconsin |

| This

paper traces the technological developments of concrete composites and

how they have emerged into a major building material. Man made materials

are now replacing basic materials as primary components in building

construction. The same phenomenon is evident in the manufacture and use

of concrete. The materials in this research

were limited to: 1. A specific class of admixture and their capabilities

as high strength agents. 2. Polypropylene fiber reinforcement. 3. Steel

fiber reinforcement. The investigation and

application for this new class of material has not yet fully been

determined. Results to date clearly identify that this material will

have an effect on primary reinforcing practices for future construction

projects. KEYWORDS:Composite,

basic admixtures, secondary reinforcing, polypropylene fiber and steel

fiber, composite fiber reinforcement. |

INTRODUCTION/HISTORICAL

DEVELOPMENT

The

basic ingredients in concrete are aggregates, cement and water. As concrete

technology developed, adjustments in the design ∎ix were perfected to

improve the ultimate strength of this material. This premise is still the goal

in concrete research today. The performance of concrete is dictated by two

variables. The first is the specific application for the material and the second

variable is the environment where the material will be placed and utilized.

Historical

records from the Unversity of Wisconsin reveal that both variables were

researched simultaneously. Through trial and error it was determined that

extreme temperatures affected the long term performance of concretes.

Research

testing proved that concrete should not freeze before reaching initial set or be

exposed to extreme heat during this hydration period. The technology of the time

led to the use of salts and sugar in the wet concrete. From this concept came

the eventual use of calcium chloride in the cement matrix. This was the start of

what is know known as admixtures in concrete. The broad term admixture now

encompasses additives which are in the form of liquid, powder and even slurry as

they are mixed into the concrete. Admixtures range from retarders, accelerators

to superplasticers.

The

second variable was the performance of the concrete. As steel became plentiful

and cost effective it became the primary reinforcement in concrete. The concept

of mechanical bonding between concrete and steel was discovered late in the last

century. Many configurations of steel size and shape were tried to improve the

mechanical bonding performance of the steel to the concrete.

According

to Ramachandran et al. [1981], a review of the U.S. Patent Office during the

1920s revealed several applications for steel fibers to be used as a reinforcing

material in concrete. This was the birth of fiber reinforced concrete (FRC).

Steel fiber reinforce concrete was finally tested for field performance in the

early 1970s. According to Yrjanson and Halm [1973], three lanes of the Tampa,

Florida International Airport were paved with steel fiber reinforced concrete

overlay. In late 1972, the most ambitious experimental fibrillated research

project was completed in Greene County, near Jefferson, Iowa. The county

engineer reported there were 3.3 miles of fibrous concrete placed as part of a

research paving project.

Many

types of synthetic fibers have been tested. The range has been wide and

extensive. The Soviet Union tested E-glass fibers with no long term success.

Nylon and rayon were tested but did not meet the performance characteristics

required for concrete reinforcement.

Polypropylene

fibers (PPF) have been used in concrete since 1965. Golfein [1965] suggested to

the

U.S. Army Corp of Engineers the inclusion of polypropylene as an admixture in concrete for use in blast-resistant

buildings. It should be noted that a British patent was registered in 1968. The

patented product was given the manufacturer name of Caricrete.

Also

during the 1920s welded wire fabric (WWF) or more commonly called steel mesh,

began to appear as an experimental reinforcement in concrete slabs. It was not

until the building boom of the late 1940s that WWF become the largest single

secondary reinforcing material in concrete. Welded wire fabric has been

specified for slab on grade use for nearly 40 years. It is the opinion of some

concrete specialists and contractors in the construction industry that little

structural value is gained from the use of the light gage WWF. What is

interesting to note however, is that light weight WWF (.135 diameter steel) was

not performance tested for many years. It was specified as a secondary

reinforcing material but a paucity of research data was not available until its

secondary reinforcement value was compared to polypropylene fibers.

MATERIAL

PERFORMANCE CHARACTERISTICS

Steel

fibers

Steel

fibers are manufactured from drawn wire. The benefits and liabilities are much

the same as primary reinforcing steel. Steel fibers are subjected to surface

deformation to improve the mechanical locking with the concrete, the same as

primary reinforcing steel. Steel fibers add strength to the concrete matrix just

like primary reinforcing. There is an optimum volume of steel fiber to improve

the performance however.

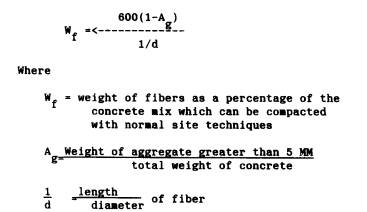

This

volume fraction term is called the aspect ratio and refers to the steel fiber

length divided by its diameter. Hannant [1978] presents and equation which is

used to estimate the approximate amount of steel fiber for aggregates of normal

density.

The

equation is:

|

The

equation is designed to be concerned with only larger aggregate because sand and

small aggregate do not effect the workability of the concrete when using fibers

in concrete.

Field results indicate that steel fiber may best be added by weight in a range from 3 to 7%. Some field reports indicate fiber volume up to 400 pounds per cubic yard. This extreme volume fraction requires an admixture such as a superplasticizer. There is a host of research reports published relating to the positive effect of steel fibrillated concrete. Conversely, there are also draw backs to the use of this product. Steel fibers are bulky and require special care during the mixing cycle. It is also labor intensive to add steel fibers during the mixing cycle. If the fibers are not mixed properly, the concrete will form into balls. Referred to as balling, the coarse aggregates and steel fibers form large balls during the mixing cycle and produce an unacceptable final product.

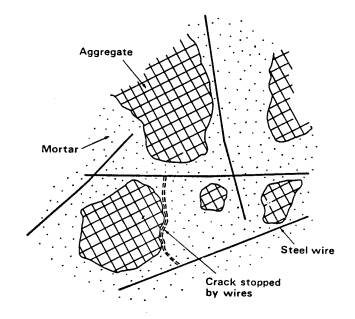

Fiber

reinforced concrete (FRC) has been proven to be a crack arrester. FRC does

eliminate most micro cracking and assists in preventing plastic shrinkage.

Figure 1 graphically presents the process for stopping crack propagation.

|

| Figure

1. Possible crack-stopping mechanism of steel fibers in concrete |

Also

pictured in this figure is the random orientation of the fibers as they lie

between the coarse and fine aggregates. This three dimensional strength

enhancement has proven very effective when comparing concrete tests in tension

and flexure.

There

is no doubt from field applications that steel fibers enhance the secondary

performance of concrete. With the use of many admixtures in concrete, care must

be taken to be sure the steel fibers are not affected by the admixture chemical

composition. One example is calcium chloride, which is a common admixture in

concrete. This salt base admixture attacks the steel fibers and causes corrosion

to form around the fibers. Edgington

[1973] has presented evidence that over a period of time, these fibers fail

structurally. As cracks appear in the concrete with age, moisture works into

these cracks. Salt erosion from highways or salt water are just a few examples.

Rust bleeding in architectural concrete is another application where damage must

be considered.

Polypropylene

fibers

Polypropylene

fibers (PPF) are utilized as a secondary reinforcement and are manufactured in

the isotactic configuration. They are extruded through a flat die and then slit

into tape form. The tape is next monoaxially stretched; this process is referred

to as "draw ratio." The draw ratio is a measure of the extension which

is applied to the fiber during fabrication, and draw ratios of about 8 (eight

times its original length) are common for polypropylene film. A molecular

orientation results from the stretching process and the resul is high tensile

strength. It may be noted, PPF is at its strongest state when placed in concrete

with tension or flexure as the primary design criteria.

The

raw material, polypropylene, derived from the monomeric C2 H6, is a pure

hydrocarbon. According to Zonsvield [1976], its mode of polymerization, its

highly molecular weight, and the way it is processed into fibers combine to give

PPF many useful properties.

PPF

has a sterically regular atomic arrangement in the polymer molecule with high

crystallinity. Its regular structure gives it the name isotactic polypropylene.

The material has a high melting point of 165 degrees C and has the ability to

withstand temperatures over 100 degrees C for short periods of time. This

temperature durability is important as secondary reinforcing material in

concrete. Polypropylene is chemically inert, which makes the fibers resistant to

most chemicals. If the concrete is exposed to aggressive chemicals, the cement

will be the first material to deteriorate.

Since

PPF has a hydrophobic surface, no additional water is needed in the concrete

mix. Because of this slick surface there is less chance for balling during the

mixing process as compared to steel fibers. Stated in textile terms, its

capabilities are 5g/denier, which is equivalent to 400 MN/m squared. Zonveld

[1976] goes on to state that this orientation leaves the film weak in the

lateral direction. This opening allows for the wet cement matrix to wrap around

the fibers during mixing, which in turn forms a mechanical bonding with the

concrete matrix.

PPF

has an advantage of being light in weight. Major North American PPF suppliers

specify its use at approximately one and a half pounds per cubic yard or about

.01% by volume per cubic yard of This is about 1.5 pounds of fiber per cubic

yard of concrete. Generally steel fibers will be added at 100 pounds per cubic

yard of concrete.

There

is no special mixing requirement necessary for PPF when mixed in the traditional

over-the-road concrete nixing truck. Forte Corporation (one major supplier),

specifies that PPF can be added at the batch plant or on-the-job site prior to

the placing of the concrete in its forms. One major concrete supplier in the

Midwest reported that adding the polypropylene fibers with the coarse aggregates

caused the fibers to open up sooner and resulted in a more homogeneous fiber

distribution. This firm also claimed that this extra step eliminated all balling

problems which resulted in delivery of a consistent high quality concrete for

contractors.

Just

as every material has useful applications, when utilized in a large variety of

settings, shortcomings do exist with polypropylene fibers. Even though PPF has a

high melting temperature compared to other polymers, it does not withstand heat

from fires in structures. When exposed to extremely high temperatures, which is

common in fires, PPF vaporizes and leaves a void in the concrete equal to the

volume of the original PPf in the mixture. This void left after a fire also

creates a porosity condition in the concrete which can not be corrected.

Since

PPF has a low modulus of elasticity, a high strain rate occurs before multiple

cracking appears. When compared to steel, which has higher modulus of

elasticity, PPF does not react in the same manner as steel. Between steel and

concrete, there is a close coefficient of expansion and contraction. Once a

crack occurs in concrete, the steel reinforcing assumes the total load for the

concrete mass. This creates a safety net, so to speak. PPF and concrete react

very differently. Because of its low modulus of elasticity, the polypropylene

fibers, directly assume the load until pullout occurs along the surface of the

fibers. At this point, known as the modulus of rupture (NOR), ultimate failure

occurs. In some testing, NOR in PPF is higher than in secondary steel

reinforcing. It should be recognized that there is a larger coefficient of

expansion and contraction between PPF and concrete than there is between steel

and concrete. This accounts for some of the differences in the behavior of this

material.

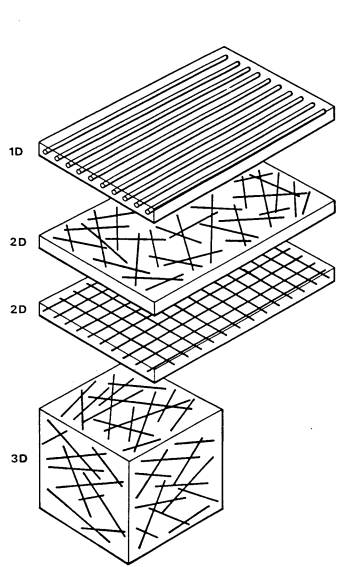

In

Figure 2 is a drawing which depicts the classification of fiber arrangements. As

can be viewed in specimen 1D, the fibers are aligned in a single plane, are

parallel to the longest side, and are centered in the object. A matting

arrangement is presented in specimen 2D. This is a newer configuration of PPF,

which has been recently field tested. In the cube marked 3D, or three

dimensional, is a specimen which shows how PPF is mixed throughout the concrete

matrix. When random fibers are mixed throughout the concrete, a three

directional reinforcing matrix develops. It should be understood that steel

fibers are linear in this three directional reinforcing. Polypropylene fibers,

being flexible, will wrap themselves around the coarse aggregates in a some what

different configuration.

|

| Figure

2. Classification of fiber arrangements |

Chemical

admixtures

The

two chemical admixtures chosen for investigation in this study were experimental

additives. The process used to introduce these admixtures into the concrete was

also an experimental procedure. The first chemical admixture tested was oleic

acid. This is a natural chemical which is obtained by the hydrolysis of

vegetable fats, primarily from olive oil. It is separated from the olive oil by

the double fractionation urea aducts process. The chemical makeup is C 76.54%, H

12.13%, and 0 11.33%. Because this chemical is an experimental admixture the

performance of this chemical will be explained in detail the discussion section.

Basic-H

is a commercially produced solution supplied at full strength as a 28% water

solution base. The chemical is a nonionic surfactant of linear alcohol

alkoxylates. The manufacturer specifies that this agent when used as an

admixture will improve the strength of the concrete.

EXPERIMENTAL

DESIGN AND ANALYSIS

The

results reported in this paper were selected from two separate investigations.

One covers results from the chemical admixture composite group and the second

reports results of composites in relationship to secondary fiber reinforcement

only. The experimental designs for both projects are the same. The testing

procedures that both investigations followed conformed to standard concrete

practices of The American Society for Tests and Measurements (ASTM) and the

American Concrete Institute (ACI).

Both

experiments are factorial designs. The cast specimens were mechanically tested

and the data was evaluated using the statistical analytical system. Each project

was designed to compare samples from the control group with samples in the

treatment group. All groups are fully randomized, replicated and verifiable

statistically.

Chemical

treatment investigation

As

reported earlier the two chemicals tested in this project were oleic acid and

Basic-H. The process chosen to inject the chemical admixture into the concrete

was to coat the polypropylene fiber surfaces with the admixture. Each set of

fiber groups were allowed to soak in a designed chemical bath for 10 minutes and

then allowed to air dry. At a later time the surface treated PPF were introduced

into the concrete while it was being mixed.

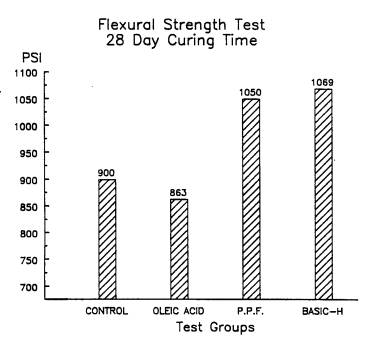

As

can be seen on Figure 3, there is a control group concrete with no fiber

reinforcement. The three treatment groups are listed as plain polypropylene

fibers (no chemical admixture surface treatment) polypropylene fibers with oleic

acid on the surface and polypropylene fibers with Basic-H on the surface.

|

| Figure

3. Flexural test comparison |

Results

from the flexure test indicate the Basic-H admixture treatment group achieved

the highest strength values after 28 days of curing time. These results are the

averages of 14 test beams in each group with a total of 56 beams overall. All

flexure tests were conducted following ASTM procedures conforming to C-78

specifications.

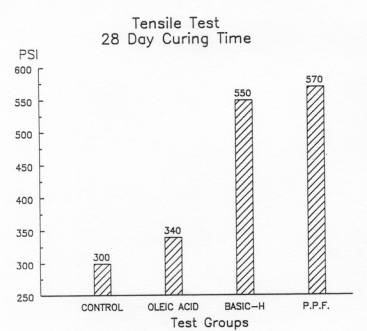

Presented

in Figure 4, are the tensile test results after 28 days curing period. In this

test there were a total of 6 samples tested in each group. In all testing, each

group was split and replicated to improve the reliability of the research and

statistical results.

|

|

Figure

4. Tensile test comparison |

Composite

fiber investigation

This

second part of the investigation reports concrete enhancement through the use of

composite fiber reinforcement, since steel and polypropylene fibers have been

tested extensively individually.

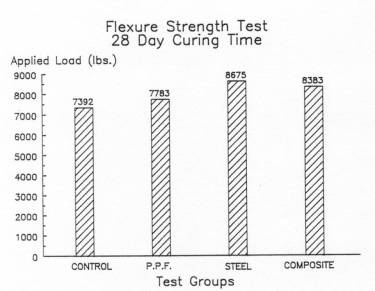

Reported

in Figure 5 are the results of this composite. This test was conducted with a

total of 24 flexural beams. The averages are reported on this bar chart. To date

these two materials have been tested with commercial admixtures. Dr. Naamen at

Michigan State and other researchers have reported their findings.

PRESENTATION

OF DATA

The

mechanical testing results of the concrete specimens are listed on the figures.

The flexure test was conducted with two measures for each sample. A direct

measure was calculated for the elastic limit of the beam at center point, more

commonly referred to as "E". The second measurement calculated was the

modulus of rupture (MOR). The modulus of rupture is calculated from the

relationship

|

|

| Figure

5. Composite fiber flexure test |

The

modulus of rupture of the strongest treatment group was the Basic-H enhanced

fiber treatment. Conversely the weakest set was the oleic acid group. The

composite fiber tensile test revealed the steel fiber group reached the highest

applied load at first crack failure of the concrete. The tensile test was

conducted utilizing the tensile briquette technique. Since the cross sectional

area of each specimen is one square inch, a direct conversion is calculated from

the applied load.

DISCUSSION

Mechanical

testing of concrete will generate data to analyze and reveal a statistical

inference from these results. There are other additional methods of analysis to

assist in explaining these test results. One tool available is the use of

nondestructive evaluation. The scanning electron microscope (SEM) is a powerful

tool to assist in materials research. A brief summary of the scanning electron

microscope findings is included to help explain the results of the plain

concrete, concrete with plain polypropylene, and PPF treated with oleic acid or

Basic-H. As can be viewed in Figure 4, there is a statistical significance

between plain concrete and PPF with Basic-H.

Chemical

fiber treatment

The

data reported here are the first results of several investigations using oleic

acid and Basic-H as an admixture. The reader can see that the findings presented

in Figures three and four do not clearly indicate which chemical treatment had

the highest and consistent performance enhancement in the concrete. One of the

goals at the beginning of this research was an attempt to improve the

interfacial bond between the polypropylene fiber and concrete matrix.

The

oleic acid SEM micrographs revealed a crystalline matrix at the fiber interface.

There was no doubt that an interfacial chemical enhancement was achieved. Why

had this bonding not improved the overall ultimate strength of the concrete? Not

until careful examination of the SEM photos was it discovered that the

crystalline growth had a lower elastic modulus than the polypropylene fibers.

What occurred was a failure at the fiber interface or a sleeve slipping action.

Therefore lower ultimate strengths were recorded in the oleic acid samples. This

explains the poor performance of these fibers in tension. An extensive review of

this phenomenon can be viewed in work by Lovata and Fahmy [1987].

The

results of Basic-H as an a full scale laboratory admixture are not conclusive.

The test results from several investigations indicate potential use of this

chemical as an early high strength concrete enhancer. It can be reported that

long term testing (45 day tests) of Basic-H had not revealed a statistical

significant improvement in the concretes ultimate strength.

Composite

fiber treatment

The

fiber flexure test reveals the averages at first failure in the concrete. As

observed in Figure 5, there is a modest gain in the performance of the concrete

with polypropylene as a secondary reinforcement. From this one observation (at

first crack observation) it appears the steel fiber reinforced concrete has the

highest potential for ultimate strength. It should be understood that in the

stress strain relationship where concrete is subjected to tension or flexure the

concrete will crack. What happens after that initial failure is referred to as

the post peak loading condition.

The

same concrete failure occurs whether it is in a laboratory situation or field

application. Once the concrete cracks, the primary reinforcement, steel re-bars

and secondary reinforcement, fibers assume the load for the structure. Therefore

the long term performance of the concrete or post fracture condition must be

considered. Shah et. al.[1988] has reported findings regarding this condition.

The performance results from the composite fiber concrete reveal a change in the

elastic limit "E" value of the concrete. After the first crack was

recorded in the composite concrete, the post-peak loading curve indicated a

change in performance compared to the steel fiber reinforced concrete. The

composite concrete sustained (by time) a much higher load curve.

Once

the composite post-peak loading situation is fully investigated and reported, it

will no doubt will have a long term effect on the future design of composite

fiber reinforced concrete.

CONCLUSION

This

investigation verifies that experimental chemicals and composite fibers can

improve the overall secondary reinforcement performance of the concrete matrix.

ACKNOWLEDGMENT

This

research was sponsored in part by Forta Fiber Corporation, Grove City, PA.

REFERENCES

|