(pressing HOME will start a new search)

- ASC Proceedings of the 39th Annual Conference

- Clemson University - Clemson, South Carolina

- April 10-12, 2003 pp 315-324

|

(pressing HOME will start a new search)

|

|

Case

Study of the Implementation of the Performance Information Procurement System at

the Dallas Independent School District

|

|

The

Dallas Independent School District (DISD) attempted to solve management

issues and construction performance issues in their maintenance and

repair program by implementing a performance based procurement system.

The test utilized the Performance Information Procurement System

(PIPS) on several roofing projects.

The hypothesis was that by replacing management and control with

information technology, competition and performance would increase,

price would be maintained, and management requirements would decrease.

The hypothesis was that construction nonperformance was an

industry structural problem and a business problem and not a

construction technical problem. The

result of the implementation was that by minimizing management and

control of the contractors and manufacturers, and using information

technology and processes, DISD received better performance for a lower

price with increased competition. The

results of the DISD implementation support the theoretical hypothesis

that the construction industry is unstable and its major problem is a

business issue, which may be solved by using information technology.

Keywords:

performance information, best value, minimizing risk, alternate delivery

methods, Performance Information Procurement System (PIPS). |

Introduction

The

Dallas Independent School District (DISD) has had a history of problems with

delivering performing construction. DISD

was using the design-bid-build process, which is typically referred to as the

low-bid process, and it is the most common procurement method throughout the

construction industry. However,

this process has been plagued with non-performance, such as not finishing on

time, not finishing within budget, and providing a product that did not meet the

owner’s quality expectations (Illia 2001, ENR 1997, Post 2001, ENR 2001, ENR

2001, Rosta 2001, Rosenbaum 2001, ENR 2002).

Agencies nationwide have been searching for alternate delivery systems in order

to improve their end products (Angelo 1997 & 2001, ENR 2001, Illia 2001).

The Performance Based

Studies Research Group (PBSRG) at Arizona State University (ASU) proposed to the

DISD, that it was not only the delivery process, but also the selection method

that was causing the poor performance. PBSRG

also proposed that the DISD could achieve the following based on a theoretical

foundation of information theory and past tests of the information theory:

Industry

Structural Stability

The authors propose

that industry structural instability is the major cause of construction

nonperformance. The instability is

caused by poor business practices, which are encumbered by non-value added

functions. Figure 1 shows the

industry structure based on competition and performance. Worldwide price pressures and the owner’s motivation to get

the best price, has moved the industry into Quadrants I and II.

Quadrant I is the design-bid-build or low bid environment.

Quadrant II is the best value (performance and price) environment. Figure 2 shows that Quadrant I is controlled by the design,

construction management, and inspection, while Quadrant II is controlled by the

performing contractor who has been selected by best value.

The performance environment moves the risk from the owner or buyer to the

contractor or vendor. This by definition is “performance contracting,” the

identification of the requirement but not how to do the requirement (DUSD 2001,

OAM 2002).

|

|

|

Figure

1: Construction

Industry Structure (CIS) |

|

|

|

Figure

2:

Factors of the CIS Quadrants |

Quadrant I has the

following poor business practices:

The authors propose

that by using information technology (performance information, Information

Measurement Theory (IMT),) and minimizing subjective bias, management, and

control, a user can move from Quadrant I to Quadrant II.

This move would increase performance, increase competition, maintain

price, and minimize management, control, and the need for subjective expertise.

The authors propose that by transforming engineers into “information

workers,” owners and buyers of construction can solve the industry instability

problem. One of the difficulties in

making the movement is the large number of current participants in the

construction industry who have built their business based on the functions

required in Quadrant I. These

companies would lose their competitive advantage (or be forced to change their

functions) if the use of IMT and performance information changes the environment

from Quadrant I to Quadrant II. A

Quadrant I environment, because it lacks information, has the following

conditions:

Performance Information

Procurement System (PIPS)

PIPS

was developed by Dean Kashiwagi at ASU in 1991, and modified and improved from

1994 to the present through over 350 tests.

PIPS has been used successfully in the private sector (Motorola,

Honeywell, Intel, IBM, and United Airlines) and on all levels of government

(Federal Aviation Administration (FAA), State (Wyoming, Hawaii, Utah, and

Georgia) and local levels (University of Hawaii and the Dallas Independent

School District.) Results include

(Hawaii 2002):

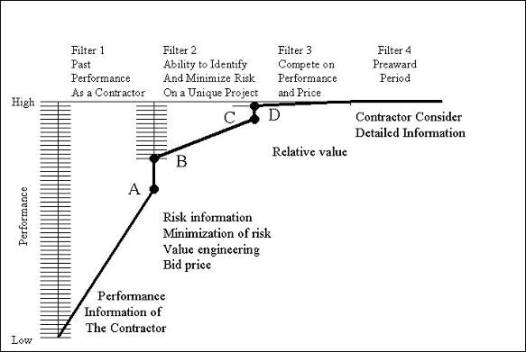

PIPS

is schematically shown in Figure 3. PIPS

has a past information phase where contractors submit a reference list and the

owner collects performance information from the references.

A management plan was required from the alternatives to identify risks,

how they will minimize the risk, and how they will add value to the project.

A prioritization phase included the use of an artificial intelligent

processor (Zeleny 1982).

The final part included the pre-award

phase, which requires the contractor to make any clarifications.

The contract is then awarded and the contractor is responsible for

meeting the owner’s expectations.

Figure

3: Minimization of

Risk using PIPS

The

differences from other best value or alternate delivery systems is the PIPS

includes all the following characteristics:

History

of the Dallas Independent School District (DISD)

The

Dallas Independent School District is the 10th largest school system

in the nation (Keller 1997).

With an approximate $980 Million in their general operating budget, the

District is responsible for 218 schools located within a 351-square-mile area (DISD

2001). Unfortunately,

within the last six years, the DISD has been plagued with corruption charges. The FBI has investigated various public officials for

extortion, bribery, massive overtime fraud, mail fraud, intentional

misapplication of funds, and other charges (Keller 1997, Schutze 1997& 2000,

Kopenec 1997). Several employees

have been found guilty, including a former Dallas School District Superintendent

(Keller 1997).

The challenge to DISD and PBSRG was to see if PIPS could be implemented

in an environment that has been vulnerable to corruption and mismanagement. They

have also been hampered by the low quality of poor performing contractors.

DISD managers were seeking a process that minimized management, increased

value and performance within the budgets of the DISD.

Objectives

of DISD

In

the summer of 2001, the DISD partnered with the PBSRG to run a prototype test on

9 different roofing projects. The objective was to implement and evaluate the PIPS process

to see if it could produce the following goals:

The

scope of work for the prototype PIPS test was to use the process to re-roof 9

school buildings. The total size of

these buildings was approximately 500,000 square feet, and the estimated budget

was $5 Million.

DISD

/ PIPS Process Modification

Being

a public entity, the DISD had certain legal constraints. DISD used the Design-Build delivery system to implement PIPS.

The process required the following modifications:

The

detailed steps for DISD are listed below:

Difficulties

with Implementation

The

following problems were encountered in the implementation:

The

DISD test verified that the roofing sector is in Quadrant I.

The majority of the roofing contractors and manufacturers do not know the

performance of their systems. In

general, roofing contractors and manufacturers are not experienced in checking

back with customers and getting customer satisfaction and performance

information. They do not regularly check their roof systems, and do

not know the owner’s representatives who are tracking the roof performance.

Warranties minimize the liability of the manufacturers through the use of

exclusions and are not determined by proven performance.

DISD

was used to getting two to three roofing contractors and two to three

manufacturers to bid the re-roofing projects.

Due to the motivation to get more contractors and manufacturers involved,

the DISD project manager, expended excessive time and effort to assist the

contractors and manufacturers. Experience

has shown that assisting the contractors and manufacturers does not result in

either higher performance by the contractors and manufacturers or more

understanding of performance. However, most users when they first implement the process

will tend to take this approach.

The

DISD project manager was not accustomed to turning the risks over to the

contractors and allowing them to perform and get rated based on their

performance. The PIPS system

identifies “turning the risk over to the contractor” as not worrying about

their performance. If problems

occur, they must solve their problems, minimizing risk and ensuring that the

user and owner recognize their performance.

One of the most difficult tasks is to allow the performing contractors to

solve their own problems and for the owner’s representative not to take any

responsibility for the performance of the contractor.

Analysis

of Results

Table

1 shows an analysis of the past performance references that were submitted.

The number of contractors increased from the usual 3 to 21, and the

number of manufacturers from 3 to 11. The

number of surveys returned was low for the manufacturers.

Table

1

Analysis of the Company References

Lists

|

OVERALL

ANALYSIS |

CONTRACTORS |

MANUFACTURERS |

|

Total Number of

Different Companies |

21 |

11 |

|

Average Number

of Contacts Submitted |

10 |

11 |

|

Average Number

of Returned Surveys |

5 |

3 |

|

Percent of

Surveys Returned |

50% |

27% |

The

results from Table 2 show that the contractors and manufacturers had information

on roofs with an average age of 4 years. The average warranty periods were 15 to 25 years.

This is troubling because owner’s perceive that the warranty period is

related to performance information. The

performance information also shows that 53% of the roofs never leaked, which

means 43% leaked for one reason or another.

This is higher than previously seen in other areas.

It is also important to note that the contractors and manufacturers are

directed to only submit roofs that show optimal performance or capability.

Table

2

Analysis of Various Performance

Criteria

|

NO |

CRITERIA |

MIN |

MAX |

AVG |

|

1 |

Average

Service Period (years) |

0.4 |

13 |

4 |

|

2 |

Percent

of Roofs that Never Leaked |

0 |

100 |

53 |

|

3 |

Percent

of Roofs that Still Leak |

25 |

0 |

1 |

|

4 |

Percent

of Jobs Completed on Time |

0 |

100 |

92 |

Other

results included the following:

The

areas that impacted the manufacturers included:

The

data shows that manufacturers do not track the performance of their roof system

in terms that can assure the buyers of long-term performance. The single most

important criteria in the second phase prioritization were the contractor’s

management plan. The management

plan score was composed up of the first phase management plan score, the second

phase detailed proposal evaluation, and the MWBE evaluation.

The reason that the management plan category had such a strong impact was

due to the MWBE evaluations (see Table 3).

The average rating was 4.1 out of 10 with a standard deviation of 3.2,

which caused a substantial difference in scores.

Before

the award of any of the nine projects, the DISD began to notice a change in

attitude from various contractors/manufacturers.

Roofs that the DISD were having problems with, due to finger pointing

between the contractor and manufacturer, were suddenly being repaired without

any pressure of the DISD personnel. School Districts around DISD whom the

competing contractors serviced, were also receiving an upgraded service.

Activities like this are not uncommon when a PIPS project is run, since

the contractors and manufacturers realize that their past performance does make

a difference on their capability to get future projects.

Table

3

Analysis

of the Management Plan Category

|

MANAGEMENT

PLAN CATEGORY |

UNIT |

MIN |

MAX |

AVG |

STD

DEV |

|

Management

Score |

(1-10) |

6.3 |

8.3 |

7.3 |

0.8 |

|

Proposal

Score |

(1-10) |

6.6 |

9.8 |

8.4 |

1.0 |

|

MWBE

Score |

(1-10) |

0.5 |

10.0 |

4.1 |

3.2 |

The

following are the preliminary results of the prototype DISD-PIPS tests:

Total

Number of Jobs: 9

Total

Number of Different Contractors Awarded a Job: 4

Total

Number of Different Systems Awarded: 2 (BUR and SPF)

Total

Budget: $4.8 Million

Total

Awards: $4.2 Million

Percent

Under Budget: -15%

Average

Length of Warranty: 19 years

The

roofs have not been completed as to date. So

far, the roofs that are constructed are above the quality of the normal DISD

roofs. In analyzing the value that

the DISD purchased, the high performance did not cost the DISD any additional

funding. To understand why, the

results of Table 4 must be analyzed to understand the hypothesis of the PIPS

system:

Table

4

Award Results of the DISD Best

Value Implementation

|

School |

1st

|

2nd

|

3rd

|

4th

|

5th

|

6th

|

Budget

|

|

Edison |

CONT

17 |

CONT

10 |

CONT

27 |

CONT

30 |

CONT

32 |

|

|

|

$

875,818 |

$

1,084,712 |

$

1,133,200 |

$

1,017,998 |

$

1,835,664 |

|

$

1,153,634 |

|

|

Carver |

CONT

17 |

CONT

10 |

CONT

27 |

CONT

30 |

CONT

32 |

CONT

29 |

|

|

$

474,418 |

$

428,540 |

$

541,300 |

$

545,820 |

$

461,415 |

$

560,000 |

$

548,347 |

|

|

Madison |

CONT

17 |

CONT

10 |

CONT

27 |

CONT

30 |

CONT

32 |

|

|

|

$

575,799 |

$

703,571 |

$

589,300 |

$

673,276 |

$

936,517 |

|

$

587,336 |

|

|

Johnston |

CONT

6 |

CONT

10 |

CONT

17 |

CONT

27 |

CONT

30 |

CONT

32 |

|

|

$

447,000 |

$

654,378 |

$

509,719 |

$

635,000 |

$

580,846 |

$

790,663 |

$

716,928 |

|

|

Donald |

CONT

10 |

CONT

17 |

CONT

6 |

CONT

30 |

CONT

27 |

CONT

32 |

|

|

$

187,054 |

$

155,694 |

$

178,000 |

$

186,498 |

$

244,700 |

$

281,746 |

$

175,576 |

|

|

Long |

CONT

17 |

CONT

10 |

CONT

27 |

CONT

30 |

CONT

32 |

|

|

|

$

425,281 |

$

529,801 |

$

501,500 |

$

512,752 |

$

875,750 |

|

$

437,080 |

|

|

Foster |

CONT

10 |

CONT

17 |

CONT

6 |

CONT

30 |

CONT

27 |

CONT

32 |

|

|

$

352,770 |

$

328,086 |

$

368,500 |

$

388,502 |

$

595,900 |

$

608,617 |

$

434,444 |

|

|

Mt.

Auburn |

CONT

10 |

CONT

17 |

CONT

6 |

CONT

30 |

CONT

27 |

|

|

|

$

406,531 |

$

365,981 |

$

533,000 |

$

420,989 |

$

487,700 |

|

$

434,120 |

|

|

Macon |

CONT

10 |

CONT

17 |

CONT

6 |

CONT

27 |

CONT

30 |

CONT

32 |

|

|

$

366,445 |

$

295,739 |

$

334,200 |

$

397,600 |

$

353,588 |

$

373,174 |

$

336,892 |

|

|

*Shaded cells represent awarded contractor. |

|||||||

Performance

does not always cost more. Contractor

#6, a very highly rated contractor who did not bid previously under DISD, won

the Johnston School with a bid over 10% under the next lowest bid, and 38% below

the budget. However, on Mt Auburn

School, they were awarded the project on the highest bid due to the better

values not being available. The

process forces a “win-win” between the contractors who are minimizing risk

and attempting to meet the expectations of the owner, and the owner who has a

limited budget.

Conclusion

The testing of the

PIPS process met the following objectives of the DISD:

Although

the construction is not completed yet, the results are similar to the results at

the State of Hawaii and other owners who have tested PIPS.

The results also sustain the hypothesis of industry structural stability

that performing contractors can perform without means and methods direction, and

best value does not always mean higher costs.

The tests also sustain the hypothesis that a user information system that

uses performance information minimizes the risk of failure and nonperformance.

Recommendations

Based

on the DISD test, PBSRG is modifying PIPS to meet the following objectives:

The

following changes are being made to the PIPS process and recommended to any

party running performance-based procurement:

These

changes reduce the management of the procurement by over 50% and the authors

propose does not increase risk. The

change to allow the vendor to send the forms to their references motivates the

vendors to know their references and also to identify their performance.

An analysis of over 100 roof procurements shows that the 80% of the

inspections do not minimize risk, and the inspections are required only to

confirm very high or low performance. Because

this is a performance based system, only the high past performance becomes a

risk if not validated by inspection.

Recommend testing of PIPS continues with the optimized version.

References

Angelo,

W. J. (1997, June). Court Clears

Way For New Methods.

Engineering News Record, 238[24], 10.

Angelo,

W.J. (2001, June). Web Voters Seek

Alternatives. Engineering

News Record, 246[25], 107.

Dallas

Independent School District (DISD) (2001).

http://www.dallasisd.org/

Decadence

in Big D. (1997, April 25). Houston

Chronicle Dallas Bureau, (Jim Schutze, author).

Deputy

Under Secretary of Defense (2001) “A Guide to Collection and Use of Past

Performance Information.” http://www.acq.osd.mil/ar/

If

They Only Had A Brain. (2000, July

6). The Dallas Observer. (Jim Schutze, author).

Illia,

T. (2001, April). CM Says Local Preference Lifts Nevada Building Costs.

Engineering News Record,

246[13], 12.

Illia,

T. (2001, July).

Late, Overbudget State Job Sparks Contracting Changes.

Engineering News Record,

247[1], 17.

Illia,

T. (2001, September). Liens

Pass $56 Million Mark on Completed Intel Project.

Engineering News Record, 247[11], 12.

Keller,

B. (1997, October 15). In Plea

Deal, Dalls Supt. Admits Theft.

Education Week.

Kopenec,

S. (1997, October 8).

Superintendent Agrees to Plead Guilty to Embezzlement.

Abilene Reporter News.

Office

of Acquisition Management, “Seven Steps to Performance Based Services

Acquisition.” 2002.

Post,

N. M. (2001, February). Beach

Development Awash in Delays. Engineering

News Record, 246[5], 56.

Rosenbaum,

D. B. (2001, February).

Contractor Says Hoover Dam Ruling Would Change All Rules.

Engineering News Record, 246[5], 12.

Rosta,

P. and Korman, R. (2001, July). Jury

Deliberates Damages as Tutor’s Methods are Debated. Engineering News Record, 247[5], 11.

Staff

Writer (1997, June). A Defining

Moment. Engineering News Record,

238[25], 58.

Staff

Writer (2001, August). Hong

Kong’s Contractors are Failing at a Growing Rate.

August 6, 2001. Engineering

News Record, 247[6], 16.

Staff

Writer (2001, August). Nevada

Removes Contractor. Engineering News Record, 247[9], 15.

Staff

Writer (2001, August) San Diego Wants to Tighten Focus on Responsible Bidders.

Engineering News Record, 247[9], 15.

Staff

Writer (2002, February). California Court Limits Change Order Claims.

Engineering News Record, 248[5],

7.

State

of Hawaii, “Report for Senate Concurrent Resolution NO.39 Requesting A Review

of the Performance Information Procurement System (PIPS)”.

PIPS Advisory Committee. November,

2002.

Zeleny,

M. (1982). Multiple Criteria Decision Making.

New York: McGraw Hill.