|

(pressing HOME will start a new search)

|

|

Knowledge Acquisition and Knowledge Structure for the Safety First Expert System

Carlos

A. Vargas and Fabian C. Hadipriono

Department

of Civil Engineering

Ohio

State University

Columbus,

Ohio

|

Construction fall accidents have been identified as a leading cause of construction injuries and deaths. Unfortunately, most literature does not adequately address the causes of falls. The knowledge of experts in the construction safety field has been underutilized and should be used to identify the causes of construction falls. To take advantage of this knowledge, the SAFETY FIRST expert system is being developed. The objective of the system is to assist in the determination of the causes of fall accidents and recommend ways to prevent their future occurrence. Throughout the development process of SAFETY FIRST, the importance of the knowledge acquisition and knowledge representation tasks was highlighted. This study reveals the feasibility and importance of using experts' knowledge to determine the causes of construction fall accidents and the advantages of using fault tree structures to represent this knowledge. Keywords: Knowledge Acquisition, Knowledge Structure, Safety, Construction Falls, Floor Edge, Expert System. |

Introduction

In

the United States, construction fall accidents have been identified as a

leading cause of construction injuries and deaths. Furthermore, OSHA has found

that falls make up about 33 % of all construction-related fatalities [Korman

et al. 19901. This trend has prevailed despite attempts by government

regulatory agencies and industry-related groups to reverse it.

The

first step in solving this problem is the identification of the causes of

these fall accidents. Once this is done, both construction companies and

government agencies will be able to focus their attention on the "weak

links" (problem areas) of construction sites and take the corresponding

safety measures to prevent their occurrence. As a consequence, the number of

disabling and fatal injuries in construction sites may be reduced

substantially.

Unfortunately,

the causes of construction falls are seldom discussed in detail in the

existing literature. In addition, experts' knowledge and experience are too

rarely used in investigating the causes of construction falls. Both of these

factors prompted the development of SAFETY FIRST, an expert system whose

objective is to assist in the determination of the causes of fall accidents.

This work is based on an earlier study used to develop FTES FALL, a fault tree

expert system prototype developed for falls investigation [Hadipriono 1992].

The earlier and most important stages in developing this system are the

identification of the causes of fall accidents in the construction industry

(i.e., knowledge acquisition) and the representation of this knowledge in the

form of fault tree structures (i.e., knowledge representation). Although

these~stages are the focus of this paper, a discussion of the architecture of

SAFETY FIRST is essential to illustrate their importance to the development

process.

The

Architecture of Safety First

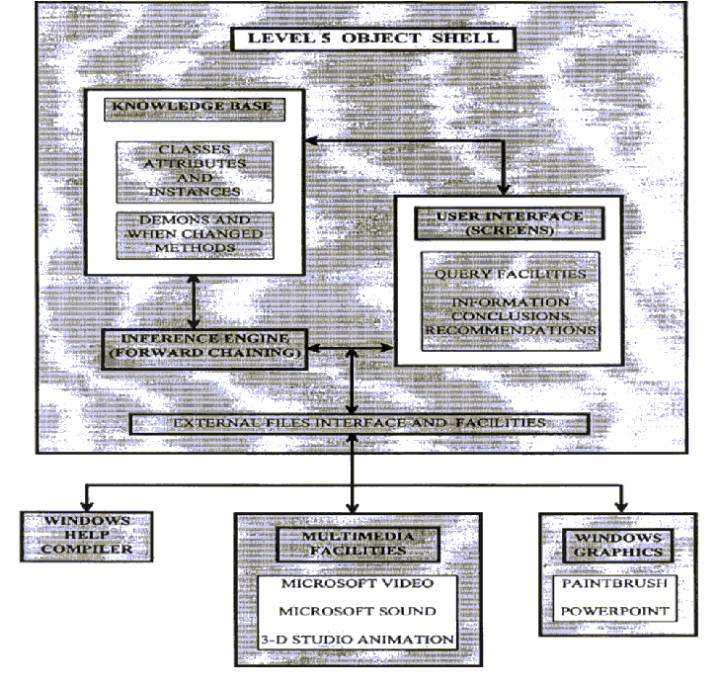

The

SAFETY FIRST expert system has two main functions: to determine the cause(s)

of a fall accident that has already occurred and to identify potential problem

areas (weak links) regarding fall safety in a construction site. To perform

these tasks, the system consists of five main components: the knowledge base,

the inference engine, the user interface, the external files interface, and

the external files (Figure 1). The first four components are all contained

within the Level 5 Object expert shell selected to develop the system. This

shell was selected because it provides all the necessary facilities to assist

the developer in the construction of the knowledge base, and, fiuther more, it

allows for the development of a user-friendly program.

|

|

|

Figure

1.

The Architecture of SAFETY FIRST |

The

knowledge base contains all the knowledge obtain from the experts regarding

the causes of construction fall and the process they follow to identify these

causes (mainly heuristic knowledge). This knowledge is represented b using

fault tree structures which can be represented in the system's knowledge base

by a combination of production rules and objects.

All

of the events and causes in the fault tree knowledge structure are represented

as either classes, attributes, or instances in the knowledge base, while the

logical or empirical relationships among these events or causes are

represented in the knowledge base by using production rules.

In

order to reach a conclusion (causes of a fall accident or weak links in a

construction site), the system needs to know the conditions in the

construction site at the time the fall occurred or the current safety

conditions in the site being evaluated. This is the main task of the user

interface r mechanism: prompting the user for the information required to

solve a problem. Other tasks of this component are to provide help to the

user, to explain why a given conclusion has been reached, and to provide

recommendations on how to avoid future fall occurrences. To do this, the user

interface has to be able to interact with all the other modules of the system.

It interacts with the inference engine and the knowledge base to determine

what information should be required from the user. Finally, it interacts with

external files to provide a more user-friendly system, including help

statements and multimedia capabilities.

Finally,

Level 5 Object also allows the system to read the external files needed during

a consultation. The inference engine determines which of these files should be

called depending on the information provided or requested by the system's

user. The SAFETY FIRST system will use the windows help compiler to provide

users with clear and friendly explanation facilities. In addition, the system

will retrieve text files containing conclusions and recommendations, and

bitmap files containing graphic samples of conditions in a construction site.

Finally, in order to make the system even more user-friendly, we take

advantage of multimedia facilities like video (using Microsoft Video), sound

(using Microsoft Sound), and animation (using 3D Studio). Fall accidents are

rarely captured on video, and pictures cannot give a user an accurate idea of

the mechanisms involved in a fall. This is the reason for the use of the

animation package. It provides the user with a simple simulation of the ways

in which a fall from a given structural component may occur.

In

order to construct the knowledge base of SAFETY FIRST as described above, the

knowledge to be used had to be acquired. This was mainly done during the

knowledge acquisition and representation tasks which are the focus of the rest

of this paper.

Knowledge Acquisition for “Safety First”

Generally,

knowledge acquisition is defined as "the process of eliciting and

enumerating the knowledge of an expert in a particular field (domain) so that

this expertise can be coded into an expert system" [Bride and Blount

1989]. During this stage most of the knowledge required to create a decision

support system is acquired, analyzed, and organized. This section includes a

general description of the knowledge acquisition process for the SAFETY FIRST

project.

In

general, three parties play an important role in the success of the knowledge

acquisition process: the knowledge elicitors, the knowledge programmers, and

the experts. The knowledge elicitors are in charge of interviewing the experts

and trying to elicit knowledge from them. They also plan the topics to be

covered during the interviews and lead the flow of the conversation so as to

maximize the amount of useful information obtained. The knowledge programmers,

sometimes called software engineers, are in charge of taking the knowledge

elicited from the experts and converting it into structures and codes that can

be used in the computer. Both the knowledge elicitors and the software

engineers are also known as knowledge engineers. Finally, the experts are the

people whose knowledge or experience in a given domain is going to be

represented by an expert system. The experts also verify the applicability and

correctness of the expert system and indicate whether or not changes are

necessary.

The

knowledge acquisition process is generally subdivided into four phases: the

preliminary, intermediate, advanced, and organization phases. The preliminary

phase of the knowledge acquisition process involved several activities,

including reading articles and any other literature available on the subject,

selecting the professionals who qualify as experts in the field, and finally,

meeting the chosen experts and asking them to participate in our project. The

authors performed the function of knowledge elicitors and knowledge

programmers.

For

the preliminary selection of the experts, three points were considered. First,

the expert had to be recognized by people in the industry as knowledgeable in

the general area of safety and, specifically, in the construction falls area.

Second, the expert had to live within our proximity so that he/she would be

easy to reach at all times. A final consideration was the amount of time the

expert was willing to give to this project. All of the experts chosen were

willing to dedicate a reasonable amount of time, given the constraints of

their jobs.

After

the experts were selected, the first interview with each of them was

conducted. The main objective was to make the experts and the knowledge

elicitors feel at ease with each other. During this interview, there was a

preliminary discussion about the project, the characteristics of the research

process, and the goals of the project. At that time, the objectives of the

project and the process required to develop an expert system were explained to

the experts. Finally, the knowledge elicitors and the experts decided on the

best place and time to meet for future interviews and any other rules to be

considered (e.g., whether or not the expert(s) would allow the knowledge

elicitor to record their conversations).

At

the beginning of the first interviews, the experts seemed to be hesitant about

the project and its objectives. For example, when the knowledge elicitors

asked one of the experts if their conversation could be taped, the expert's

reservations about the project were evident. The immediate response was

"no." The expert cited legal problems to explain his answer. In the

interview, Any questions the experts had about the project or expert systems

over all were answered. Finally, during this discussion the participants got a

chance to know each other and to lay a good foundation for future interviews.

Next,

in the intermediate phase, the objective was to focus the experts' attention

on the subject matter. To do this, we created a questionnaire which served as

the second interview with each of the experts. The focus of this questionnaire

was on construction falls from high elevations and it was developed to try to

get each expert to think about construction falls, first generally, and then

in more specific terms. After these interviews, the knowledge acquired was

reviewed and the topics of the next interviews were determined. These topics

included areas that had not been fully explored, or which were still not clear

to the knowledge elicitors after review. Finally, by the end of the

intermediate phase, we had developed preliminary fault tree models for all of

the building components considered significant enough to be included in this

project (e.g., a roof, a floor opening, etc.).

Once

the interview process reached the advanced and organization phases, the

interview topics concentrated on specific details regarding construction falls

from the selected components. The experts also checked the preliminary fault

trees and suggested changes to them (as needed). In addition, any

disagreements among the experts were settled by providing them with more

specific explanations of the variables and parameters involved in the subject

at hand. For example, for a sloped roof component, there was disagreement on

whether or not devices like crawling boards, roofing brackets, and the

so-called chicken ladders could prevent falls. Some of the experts seemed to

think so, while others disagreed. In this case, after further discussions, we

agreed that those devices are useful tools that help a worker perform his/her

job on a sloped roof, but they, by themselves, cannot prevent the worker from

falling and/or protect him/her from injuries if a fall occurs.

All

of the interviews were summarized and kept on record in order to be used later

in the knowledge representation phase. These summaries contain the most

significant information acquired and, depending on whether the expert allowed

taping, they were obtained after careful review of the interview tapes or from

the notes taken by the knowledge elicitor during the interviews.

As

mentioned before, the knowledge acquisition and the knowledge representation

tasks occurred simultaneously starting from the intermediate phase. The

knowledge was represented through fault tree structures. In the next two

sections, we discuss the fault tree development process: first, by providing a

brief introduction to fault tree analysis and, second, by explaining the

development process for one of the structural components studied during this

project.

Fault Tree Development for Safety First

There

are two types of analytical processes that can be used to analyze a system:

inductive or deductive. For a system failure analysis, inductive techniques

would attempt to find out what would happen if some fault occurred in the

system and all the possible failures that may result as a consequence. For

example, if we take the fault "the worker is intoxicated in the

construction site," there are several failures (accidents) that may

result as a consequence (e.g., the worker may fall, be electrocuted, or be

caught-in between some equipment). Therefore, through this method we can

evaluate the importance of avoiding the occurrence of certain events (faults)

in the system.

The

deductive method takes a different reasoning approach going from a given

failure mode (consequence) to the specific causes that may lead to it. In this

case, we consider a given type of system failure (e.g., worker fall) and try

to determine what specific faults (e.g., worker has health problems or worker

is hit by something) may cause or contribute to its occurrence. The fact that

we can focus on one failure mode and determine how it can occur is the main

reason why this type of analysis is used in this project. The focus of this

project is in the causes that may lead to a fall accident. The significance of

a given cause regarding other failure modes is not within the scope of our

study.

Fault

tree analysis is a typical deductive analysis method which seeks to identify

all of the failure modes that can cause a system failure (top undesired

event). In the Fault Tree Handbook, Roberts et al. [19811 defined a fault tree

as a graphic model that shows "all the various parallel and sequential

combinations of faults that will result in the occurrence of the pre-defined

undesired event." The objective of a fault tree is to identify all the

possible ways (paths) in which the top undesired event may occur. Through this

method the analyst can also identify potential "weak links" in the

system being studied and, as a consequence, prevent serious problems or

accidents. It is important to note that the fault tree model is limited in

that it only depicts the events or combination of events that in the analyst's

opinion can lead to the top event's occurrence. Therefore, the scope and

limitations of the analysis must be carefully defined and all the assumptions

clearly stated. Otherwise, there is a chance that the analyst may omit

important input causes.

The

events contributing to the occurrence of the top undesired event are

determined through the use of logic gates, which show the events or

combination of events needed for the occurrence of a higher event. Given a

specific gate, the higher event is the output of the gate and the lower events

are the inputs to the gate [Roberts et al. 1981]. The relationship among the

input events is defined by the type of gate used to connect them. There are

several types of events and gates symbols However here we will only discuss

those used for this project. We will employ the symbols used in the Fault Tree

Handbook published by the National Technical Information Service [Roberts et

al. 1981 ].

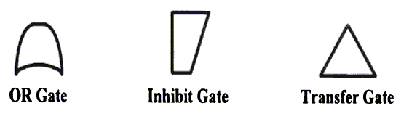

Three

types of gates are used in this paper's fault trees: OR, INHIBIT, and TRANSFER

gates (Figure 2). The OR gate indicates a situation in which if at least one

of the input events occurs, then the output event happens. Next, the INHIBIT

gate is used if a basic or primary event occurs simultaneously with a

conditioning event, leading to the output event. In this case, the top event

happens if a basic fault occurs in the presence of an conditioning

(restrictive) cause. Finally, the TRANSFER gate allows the user to develop a

fault tree while avoiding excessive use of symbols on one sheet. The tree can

be broken into several branches depicted on different pages. In addition, this

symbol precludes having to re-draw the branches of the tree that are identical

in several places.

The

symbols of all the events in this study are shown in Figure 3. The rectangle

defines an "intermediate event," which is a fault event resulting

from the input causes acting through a logic gate. Next, the circle defines a

"basic event," which is a cause that requires no further

development. It is also referred to as a primary or generic failure [Barlow et

al. 1975]. Further, the ellipse is used to represent a "conditioning

event," which is an event that includes any restrictions or conditions to

the INHIBIT gate. Finally, the diamond represents an event that is not

developed further, or an "undeveloped event." The reason an event is

left undeveloped is either there is a lack of information or, as in our case,

the event is outside the scope of the study.

The

fault tree system was chosen to represent the acquired knowledge because it

simulates the way experts determine the cause(s) of a tall accident that has

already happened. Several fault trees for several structural components were

developed once the knowledge acquisition from the experts and the literature

was completed and the main causes of falls were identified. The final

objective of these fault trees was to show the causes or combinations of

causes that can lead to a construction fall accident from a given surface.

Therefore, the top undesired event of all the developed fault trees is

"worker falls from a [predetermined surface]." Given this event, the

primary and secondary causes contributing to the fall are determined through

the use of logic gates.

For

SAFETY FIRST, the study has been limited to developing the fault trees to

determine the causes off alls from seven elevated surfaces (floor edge, floor

opening, roof, top of wall, wall opening, steel beam, and ladder), from the

same level, and slips. Furthermore, we are only concerned with falls that

occur during vertical operations, such as the construction of buildings or

residential homes. Events like falls during bridge construction and trench

operations and falls from utility poles are excluded. In addition, we have

focused on the causes of falls over which workers had a certain degree of

control or which acted upon workers and caused their falls. Causes of falls

related to structural components supporting the workers have been identified

in other studies. They will be mentioned but not elaborated on since their

analysis would require a comprehensive structural engineering background, a

field of expertise which is not within the domain of our current experts.

The

first step in developing the knowledge representation structures (fault trees)

was the determination of the causes of falls for each of the structural

components studied. This was done during the knowledge acquisition phase of

the project. As this task progressed, the relationships among the causes and

the top event of the fault tree (worker fall) became more evident, and we were

able to represent them by using preliminary fault tree structures. Later, as

the details about the relationships among causes became even more clear, these

preliminary trees were further refined and organized in a more accurate

structure.

|

|

|

Figure

2.

Gates and transfer symbols |

|

|

|

Figure

3. Event Symbols |

In

this paper, the structure and organization of the developed fault trees is

illustrated by using the fault tree for the event in which a worker falls from a

floor edge elevated component. This fault tree will also show all the

assumptions and constraints associated with the tree's development process.

For simplicity in explaining the fault tree, first, the tree's overall structure

will be described and, second, the basic and conditioning causes of falls from a

floor edge will be discussed in general terms. In addition, a code within

parentheses will accompany the explanation of some of the possible events or

causes. This is the same code used in the partial fault tree structure depicted

in Figures 5 to 7. Within the code, the first letter indicates whether an event

is a gate (G), a basic cause (B), or a conditioning cause (C). Next, a single

digit refers to the level of the event on the tree (assuming the top event is at

level zero). Finally, the remaining number in the code designates the event

number within the level, starting from zero and moving from left to right. For

example, the code B411 indicates that the event is a basic cause located on the

fourth level of the tree and it is the eleventh basic cause within that level.

|

|

|

Figure

4. Components of a “Worker Falls from a Floor Edge” Fault Tree |

Structure

of the “Worker Falls From a Floor Edge” Fault Tree

A

"floor edge" is an elevated structural component which includes any

section of the floor perimeter which is open or unprotected. This component only

includes sections where a worker may fall toward the outside of the building

(i.e., floor openings are excluded). Any falls from this elevated component may

cause serious (if not fatal) injuries to a worker.

|

|

|

Figure

5. Fault Tree model for the “ Worker Fall from a Floor edge” top event |

As

mentioned before, the focus of our study is on the worker and all the causes of

falls over which he/she had some degree of control (enabling causes) or the

external causes which directly acted upon him/her (triggering causes). We do not

analyze in detail the causes of falls related to the failure c support

components. For the purposes of this study, we assume that the worker is being

supported by the Roof surface and that the floor is being supported by joists, a

shown in Figure 4.

To

start the evaluation, the "Worker Falls from a Floor Edge" (GTOP)

event is predetermined as the top un desire event of the fault tree model. The

causes of construction fall from a floor edge can be expanded into two major

types c events: those related to the worker (G10), and those relate to the

failure of either the support components (floor o joists; Gl 1). Because any of

the causes under these two type of events could cause a worker to fall, they are

related wit an OR gate (Figure 5).

The

branch under the worker support-related event contains any problem directly

related to the failure of the Roof supporting the worker (Figure 5). This

failure may be due to enabling (G23), triggering (G24), or support (G25)

problems related to the floor. These problems will not be developed in great

detail as mentioned in the limitations above.

On

the other branch of the tree, the causes of falls related to the worker (G10)

can be divided into three groups: the first group (G20) contains the cases for

which the worker's fall is due to a combination of either a worker enabling

(G40) or triggering (G41) basic cause and a conditioning cause, i.e., safety

problems related to fall protection/prevention (G31). Because a conditioning

cause (restriction) due to fall safety problems must be present in order for a

basic cause to provoke a worker's fall, these causes are related by an INHIBIT

gate (Figure 5).

The

second group of worker-related causes (G22) includes cases in which a fall is

due to a combination of a worker triggering (G41) basic cause and a general

safety problem conditioning cause (C30) other than a problem with fall

protection/prevention safety problems. An INHIBIT gate is used to relate these

causes because both must happen at the same time in order for a fall to occur

(Figure 5).

The

last group of worker-related causes (G21) explores the possibility that a worker

may fall despite the presence and/ or adequate use of fall protection/prevention

equipment and safety measures (Figure 5). This is only possible when the causes

of the fall are due to a selected number of worker enabling causes. Among these

causes are cases when the worker is intoxicated (B31) or under the influence of

controlled substances (B32), or when the worker has serious health problems

either acute (B40) or chronic (B41).

Causes of Falls From a Floor Edge

All

of the previously discussed branches are developed further into more specific

causes of falls. These causes which can be found at the end of all the tree

branches are presented briefly in this paper. They are discussed in greater

detail in Vargas [ 1993]. A branch of the fault tree structure developed for the

"worker fall from floor edge" event is provided in Figures 6 and 7. In

addition, a summary of the causes depicted and a brief description of them is

included in Table 1.

|

|

|

Table

1. Causes Description |

|

|

|

Figure

6. Fault Tree model for the “Worker Enabling I” event |

Basic

Causes. Basic causes are primary failure problems which either by themselves or

in combination with a conditioning cause may lead to the occurrence of a fall

accident. There are three basic causes: enabling (G40), triggering (G41), and

support-related (G11). Enabling causes (Figure 6) are related to problems

internal to the worker, like behavioral or social problems affecting his/her

concentration and productivity. They are classified into three main problems:

poor attitude (e.g., the worker goes to work drunk), health problems (e.g., the

worker has a heart attack while working), and skill problems (e.g., the worker

has not been trained). Next, triggering causes (Figure 7) include any external

event acting on a worker and leading to his/her fall. They are also classified

into three types: those due to impact on the worker (e.g., a piece of equipment

hit the worker), those due to environmental conditions (e.g., rain causes

slippery conditions which may lead to a worker fall), and those due to

distractions in the surroundings (i.e., the worker is distracted by some

occurrence in the site and did not notice a hazard to his life). Lastly, the

support-related causes include problems related to the structure or component

supporting a worker while he/she performs a job (e.g., floor failure).

Conditioning

Causes. Now let us leave the discussion of basic causes to address the

conditioning causes. These are problems or conditions in the system that, if

combined with primary causes, enable the occurrence of a fall accident. They

cannot cause a worker's fall by themselves. This does not mean, however, that

they are not important. They are considerably significant since their avoidance

can, in most cases, prevent accidents from happening. These causes are mostly

related to safety problems which can be prevented through the implementation and

use of sound safety measures in a construction site. This is important because

it means that the construction companies' management can have a great deal of

control over the elimination of falls. In this paper, two types of conditioning

causes are included: one related to problems with general safety measures (e.g.,

poor work site maintenance) and the other related more specifically to problems

with the fall protection/prevention safety measures in a site (e.g., the

inadequate use of fall protection devices like guardrails or safety nets).

|

|

|

Figure

7. Fault tree model for the “Worker Triggering” event |

Conclusions

The

identification of the more common problems or combinations of problems which

are the cause of construction falls occurring during vertical operations is

essential to eliminate these accidents. This can be done by using the heuristic

knowledge of experts regarding falls and their causes. This knowledge is

obtained through a knowledge acquisition process and then is represented in

fault tree structures which attempt to simulate the reasoning process used by

experts to determine the causes of falls.

For

the SAFETY FIRST project, the more significant causes of falls from seven

elevated surfaces (floor edges, floor openings, roofs, tops of walls, wall

openings, steel beams, and ladders) and from the same level, as well as the

causes of slips have been studied. Falls from higher elevation are studied in

more detail because, even though they occur less frequently than do those from

the same level, their consequences are more severe. Regarding workers falls from

a floor edge, it has been found that the causes of falls can be classified into

basic or conditioning ones. Furthermore, the basic causes can be subdivided into

enabling, triggering, and support-related causes; and the conditioning causes,

into general safety and fall prevention/protection problems.

In

addition, we can conclude that fault tree models have the advantage of being a

good tool to systematically represent the experts' knowledge regarding

construction falls by showing the causal relationships of all the events in the

tree. They also provide a good tool to investigate the causes of a construction

fall that has already occurred, much in the same way as an expert would (i.e.,

the branches of the fault trees represent the major paths of reasoning of an

expert when processing information available to decide on the most logical cause

of a fall). Furthermore, it has been found that these fault tree structures can

be represented in the knowledge base by using a combination of object oriented

and production rule techniques. The events and causes in the trees are depicted

as classes, attributes, or instances; while the relationships among themselves

are shown by using production rules.

Acknowledgement

This

project was supported by grant 1 KO I OH00115-01A1 from the National Institute

for Occupational Safety and Health (NIOSH) of the Centers for Disease Control.

Dr. Roy M. Fleming is NIOSH's Associate Director, Dr. S. Price Connor is the

Program Officer, and Mr. Ronald L. Stanevich is the Project Advisor for SAFETY

FIRST. The contents of this paper are solely the responsibility of the authors

and do not necessarily represent the official views of the National Institute

for Occupational Safety and Health.

References

Brule

J. F. and Blount A., (1989). Knowledge Acquisition, McGraw-Hill Publishing Co.

Business

Roundtable (1990). "Improving construction safety performance,"

Construction industry cost effectiveness project report, report A-3, January

1982, Reprinted July 1990.

CFR-29

(1988). "Code of Federal Regulations 29," Part 1926, Office of the

Federal Register National Archives and Records Administration.

Dhillon

B. S. and Singh Chanan (1981). Engineering Reliability: New Techniques and

Applications, John Wiley & sons.

Ellis

N. (1989). Introduction to fall protection, American Society of Safety

Engineers.

Hadipriono

F. C. (1992). 6Expert System for Construction Safety. 1: Fault Tree Models,6

Journal of Performance of Constructed Facilities, Volume 6, No. 4, November

1992.

Hinze

J. and Appelgate L. (1991), "Costs of construction injuries," Journal

of Construction Engineering, pp. 537549.

Korman

R., Setzer S. W., and Bradford H. (1990). "Job site dangers defy worker

protection drive," Engineering News Record, November 1, pp. 24-28.

Merritt

F. (1992). "15 facts about slips & falls," ISHN, May, pp. 28.

Minter

S. (1989). "New ways to combat costly slips and falls," Occupational

Hazards, April, pp. 61-63.

Nunnally

S. W. (1993). Construction Methods And Management, Third Edition, 1993,

Regents/Prentice Hall, pp.

OSHA,

(1987). "Construction industry OSHA Safety and Health Standards (29 CFR

1926/1910)," U.S. Department of Labor Occupational Safety and Health

Administration, OSHA 2207.

Roberts

N. H., Vesely W. E., Haals D. F., and Goldberg F. F.; (1981). Fault Tree

Handbook, National Technical Information Service, January, pp. IV-2-IV-11.

Vargas

C. A., (1993). Construction Falls: Knowledge Acquisition and Fault Tree

Development, A thesis presented in partial fulfillment of the requirements for

the degree of master of science in the graduate school of The Ohio State

University.